With the rapid development of electricity, more and more cables are used in different environments. What if in bad conditions? Then it's critical to ensure your cables run smoothly and reliably when transferring electrical energy. As the name suggests, armored cables are protected from mechanical damage, while unarmored cables are not. What's the difference between them? Why should we choose armored cables instead of unarmoured cables? Next you will find the answer you want.

Armored Cable Overview

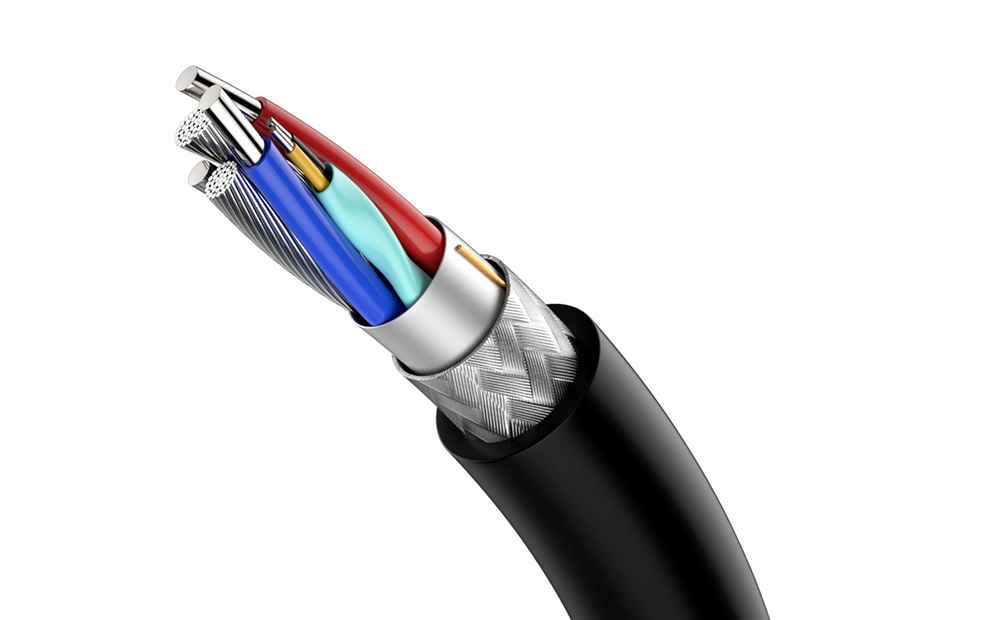

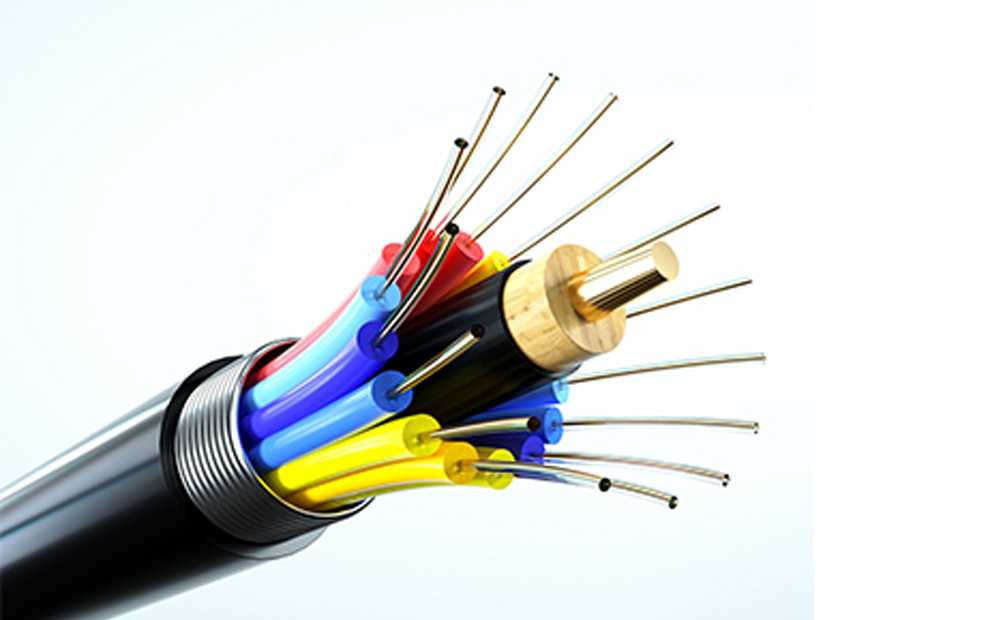

Armored cable has an extra layer of protection that prevents it from being cut or frayed. The armor of the coaxial cable is an aluminum foil wrap that is ribbed like corrugated metal to provide flexibility, and around the inside and outside of the wrap is a waterproof compound to prevent moisture from penetrating the cable and causing damage. The internal structure of the 4-core armored cable consists of multiple layers to prevent damage to the cable. The outer sheath protects against rodents, abrasion and twisting and is usually made of plastic. Armoring materials are mainly derived from Kevlar, steel and aluminum foil, and are designed to protect the armored cable from being stretched during installation.

The difference between armored cable and unarmored cable

Structure

Many people may think that armored cables only have metal protection. To be precise, the armor material does not have to be metal, it can be fiber yarn, glass yarn, polyethylene, etc. The only difference between armored fiber optic cables and non-armored cables is that armored cables have an additional outer layer to protect the cable. 4-conductor armored cables tend to be more expensive than non-armored cables, and steel tape and aluminum armored cables are much less expensive than armored cables that are often used in special applications.

Application

Armored cables are installed in locations vulnerable to mechanical damage, such as outside walls, as an alternative to conduit. Armored cables usually have a small metal strap to ensure electrical continuity to the safety ground. (You also have to run a separate ground wire in flexible conduit; you cannot rely on the continuity of the conduit.) In special cases, 4-conductor armored cable is preferred. In walls and other protected locations, less expensive unarmoured cables can be installed. Unarmored cables are mainly used in control systems.

Why use armored cables instead of unarmoured cables?

There are several reasons why armored cable should be used. The biggest reason is strength, as armored cables have been used more widely over the past few decades, when cables were just buried directly in the dirt rather than being used through conduit. Today, most local municipalities require that ducts be dug prior to installing network components, eliminating the need for unarmoured cables in most applications. Second, rodents or animals can and will bite through the cable, so the armor protects the cable from damage from animals or shovels in direct burial applications. Third, the least common reason to use it is in environments with various animals, where armor while grounded can provide another layer of protection.

Conclusion

Armored cable can be thought of as a reinforced cable that is stiffer and stronger than standard cable. The 4-conductor armored cable provides unmatched protection from physical damage without sacrificing the flexibility or functionality of the transmitted power, making it the perfect addition to any power transmission in hazardous environment.