XLPE cable is a type of power cable widely used in modern industry. As an insulation material, it has a high status in the field of cable applications and is widely used in transmission, transformation, road lighting and other fields. This blog aims to introduce what XLPE cable is, and analyze its characteristics, application scenarios, and testing schemes.

What is XLPE Cable?

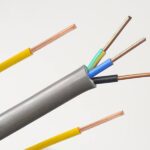

XLPE cable, also known as cross-linked polyethylene insulated cable, is a new type of high-voltage power cable. Compared with traditional PVC (polyvinyl chloride) cables, it has better performance. XLPE cable is made from polyethylene (PE) as raw material, which is cross-linked by special electronic accelerators (or chemical methods). Cross-linking technology can change the molecular structure of polyethylene, thereby greatly improving its insulation performance. In cables, XLPE cables are mainly used as insulation layers.

Characteristics of XLPE Cable

Compared with PVC cable, XLPE cable has the following advantages:

- Excellent electrical performance, with a withstand voltage performance of more than 10kV/mm.

- Good heat and cold resistance, can be used normally in the range of -90℃ to +130℃.

- Good chemical resistance and UV resistance.

- High elasticity, high tensile strength and fatigue performance, can work well under extreme conditions.

- Good flame retardancy, not easy to burn, suitable for cable applications in high-temperature environments.

Application Scenarios of XLPE Cable

Due to its excellent insulation and electrical performance, XLPE cable is widely used in various fields. Currently, XLPE cable is mainly used in the following fields:

- Power transmission and distribution: used for cable transmission in power systems such as substations and power plants.

- Communication: used as insulation material for optical cables and data cables.

- Construction: used as cables for electrical equipment in buildings.

- Metallurgy, chemical and petroleum industries: used for cable transmission of control systems and transmission equipment.

XLPE Cable VS. PVC Cable

- Dielectric Performance PVC cable and XLPE cable have significant differences in dielectric performance. Specifically, the dielectric constant of XLPE cable is lower, the dielectric loss tangent value is smaller, and its insulation performance is stronger. At the same time, XLPE cable also has higher breakdown voltage and anti-electrical breakdown ability. In comparison, the dielectric performance of PVC cable is not as stable as XLPE cable.

- Heat Resistance In terms of heat resistance, XLPE cable is superior to PVC cable. Its long-term working temperature can reach 90℃, and short-term overload temperature can exceed 130℃. PVC cable is temperature-limited and usually has a long-term working temperature of no more than 70℃. Therefore, XLPE cable is more suitable for cable applications in harsh environments such as high temperature and strong corrosion.

- Fire Resistance The fire resistance of XLPE cable is also significantly better than that of PVC cable. When burning, XLPE cable can self-extinguish and form a layer of carbon to protect the conductor, thus avoiding or reducing the occurrence of fires. PVC cable will release a large amount of toxic gas and acidic gas during the combustion process, which seriously harms the environment and human health.

- Maintenance Cost XLPE cable and PVC cable also have certain differences in maintenance costs. PVC cable is prone to aging and corrosion in harsh environments such as strong acid and alkali, so it needs to be inspected and replaced more frequently. XLPE cable has high durability and stability, and can usually operate for a long time without replacement, so its maintenance cost is relatively low.

Testing Scheme for XLPE Cable

In order to ensure the safety and reliability of the cable, it is essential to conduct withstand voltage tests, routine state evaluations, and partial discharge detection for XLPE cable. Among them, partial discharge detection is the main method for testing the on-site operation of XLPE cable. Partial discharge detection can determine the insulation status of the cable, which helps to identify problems and solve them in a timely manner. For XLPE cable partial discharge testing, power companies consider the following three aspects to organize and implement cable partial discharge detection work to cover all medium and high voltage power cables of power companies:

- Determine the measurement points and monitoring cycle: choose appropriate measurement points and cycles according to the characteristics and applications of XLPE cable.

- Determine monitoring indicators and calculation methods: monitor the physical, chemical, and electrical indicators of XLPE cable to judge its insulation status.

- Develop warning and disposal plans: discover problems in the cable status monitoring in a timely manner, and develop corresponding warning and disposal plans.

Conclusion

XLPE cable is a new type of high-voltage power cable with excellent electrical performance and durability, which is widely used in transmission, transformation, road lighting and other fields. Its excellent insulation performance and electrical performance have laid a solid foundation for the safe and stable operation of the power system. In the selection, design, construction, and maintenance of XLPE cable, its characteristics and application scenarios should be carefully considered, and corresponding testing and evaluation measures should be taken to ensure its safe and reliable operation.