TPU cable is a cable that uses thermoplastic polyurethane (abbreviated as TPU) as the insulating material. Thermoplastic polyurethane is a polymer elastomer with excellent physical and mechanical properties, chemical stability and heat resistance, can adapt to low temperature and high temperature environments, and has good self-extinguishing properties and is not easy to burn.

What is a TPU cable ?

TPU cable is a type of cable that uses thermoplastic polyurethane (TPU) as the insulation and sheath material. TPU is a polymer material with excellent physical and chemical properties, which can maintain its elasticity and flexibility under different temperature, humidity and pressure conditions.

Characteristics of TPU cable

- Wear resistance: TPU cables have high wear resistance, can resist various frictions, scratches and tears, and are suitable for use in harsh environments.

- Oil resistance: TPU cables have good oil resistance and can resist the erosion of various mineral oils, animal and vegetable oils and synthetic oils without cracking or delamination.

- Weather resistance: TPU cables have good weather resistance, can work normally in the temperature range of -40°C to 90°C, and will not harden or deform due to temperature changes.

- Aging resistance: TPU cables have good aging resistance, can resist the influence of ultraviolet rays, ozone and oxidants, and will not fade or deteriorate.

- Fire resistance: TPU cables have very good fire resistance and can maintain their structure and function at high temperatures without producing toxic or harmful fumes or gases.

- Environmental protection: TPU cable is an environmentally friendly cable that does not contain halogens, heavy metals or other harmful substances, and can be recycled or biodegraded.

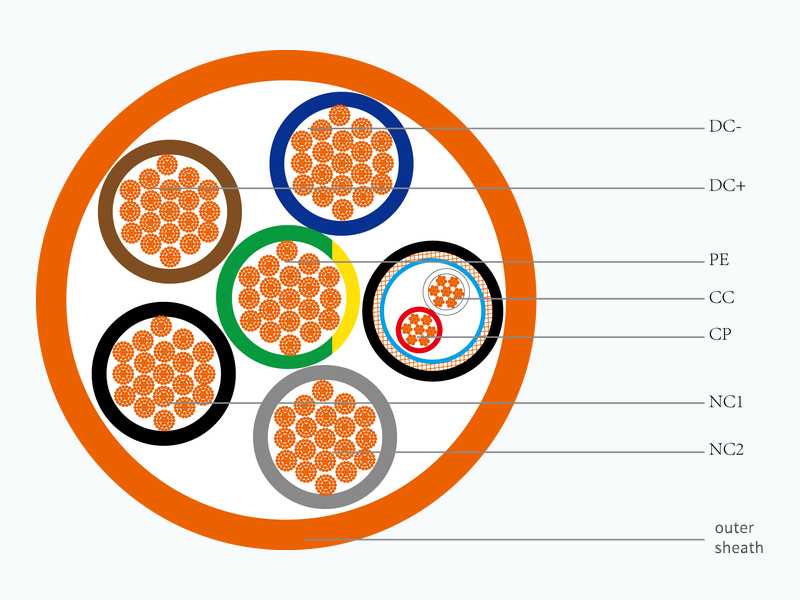

TPU cable structure

The structure of TPU cables usually includes conductors, insulation layers, sheath layers and other parts.

Conductor: The part of a cable that carries electrical energy, usually made of copper wire or tape;

Insulation layer: The part used to isolate the conductor from the external environment, usually made of thermoplastic polyurethane material. The thickness of the insulating layer determines the voltage withstand capability of the cable and its adaptability to temperature changes;

Sheath layer: used to protect the cable and prevent external mechanical damage, chemical corrosion and other factors from affecting the cable. TPU cables are usually made of polyurethane material for the sheath layer, and its physical properties such as hardness and tensile strength are relatively good.

In addition, in the actual application process, TPU cables will need to add other auxiliary structures according to different purposes, such as reinforcement layers, shielding layers, waterproof layers, etc., to enhance the durability and performance of the cables.

Application field of TPU cable

Due to its many advantages, TPU cables have been widely used in many different fields and occasions. Specific application areas include but are not limited to the following aspects:

- Machinery manufacturing industry: TPU cables are widely used in the machinery manufacturing industry, such as industrial automatic control systems, robot control systems, measurement and sensors, etc.;

- Aviation field: Because TPU cables have good high temperature resistance, they are also widely used in the aerospace field, mainly used for signal transmission and power supply in aircraft, satellites and other equipment;

- Medical industry: TPU cables are more and more widely used in the medical industry, mainly used in ultrasonic transmission lines, monitors, medical imaging equipment and other equipment;

- Communication field: TPU cables are also widely used in the communication industry, mainly used for internal connection lines of communication equipment such as mobile phones and network equipment.

Manufacturing process of TPU cable

- Cutting the conductor: Cut the copper wire or copper strip according to the required length and quantity;

- Winding conductor: winding copper wire or copper strip into the required conductor shape;

- Insulation treatment: Insulate the wound conductor and use thermoplastic polyurethane material for injection molding or extrusion;

- Sheath treatment: pass the insulated wire through extrusion or injection molding process, and put on the outer sheath for protection;

- Test: Test whether the wire meets the specified electrical performance indicators, such as withstand voltage, insulation resistance and other indicators.

Disadvantages of TPU cables:

(1) High cost: Compared with cables made of other materials, the manufacturing cost of TPU cables is higher and the price is more expensive;

(2) High environmental requirements: TPU cables need to pay attention to environmental protection during manufacturing, use and disposal, otherwise they will easily pollute the environment;

(3) Limited applicable scenarios: Due to the high cost, the application range of TPU cables is relatively narrow, and currently it is mainly used in some fields that require high cable performance.

Comparison of TPU cables and other cables

Compared with PVC cables:

Compared with PVC cables, TPU cables have better heat resistance and flame retardancy, are suitable for high temperature and flammable places, and also have better wear resistance and moisture resistance. But the manufacturing cost of TPU cable is higher and the price is more expensive.

Compared with PE cable:

Compared with PE cables, TPU cables are better in friction resistance, and have better flame retardancy and heat resistance. But compared with PE cables, the physical performance of TPU cables is relatively hard, not as soft as PE cables, and the cost is higher.

Compared to PUR cables:

Compared with PUR cables, TPU cables have better heat resistance and flame resistance, as well as better wear resistance and moisture resistance, but the cost of TPU cables is relatively high.

Conclusion

With the continuous advancement of science and technology and the continuous improvement of people's demand for environmental protection and high efficiency, the field of TPU cables will also face broader development prospects. In the future, TPU cables will continue to enhance their own cost advantages, while continuously improving their performance and reducing pollutant emissions to meet the needs of different fields in the market. In addition, with the popularization of electronic products and the continuous development of network technology, TPU cables will be more widely used in communication, data transmission, equipment control and other fields.