INTRODUCTION

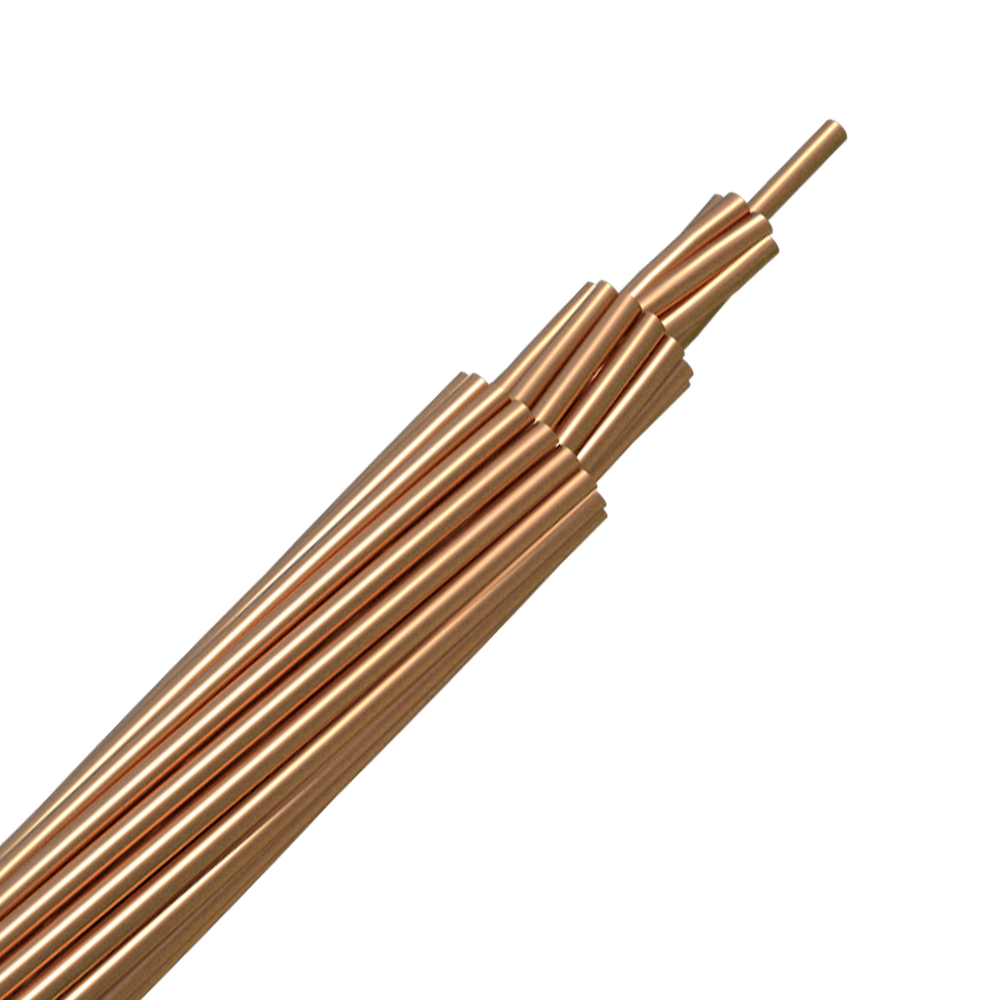

Copper Clad Steel CCS ASTM STANDARD HIGH TENSILE STRENGTH 40% CONDUCTIVITY CCS

21%, 30% and 40% IACS.

– CCS has more than 10 times the ex fatigue cycles compared to annealed solid copper.

– CCS is 65% stronger than Annealed Copper.

– CCS is more robust than Annealed Copper.

– CCS can be thermo or Cad Welded just like Copper.

– CCS has faster impedance to ground than Copper, so lines and equipment have a better protection.

– CCS has higher resistance to thermal expansion Failures when compared to solid copper.

– CCS has the same resistance to corrosion as copper.

– The main applications for CCS are the CATV Drop Wires, Telepho- nic Wires, Grounding Applications and Aerial Cables.

APPLICATION

Telecommunications

Utility Industry

CCS for grounding application

Wind Power

Tracer Wire

Cable manufacture

Automotive

Other applications

FEATURES

• Demonstrates the same corrosion-resistant properties as copper while maintaining the high strength of steel

• Reduces damage caused during installation or fatigue from vibration or bending

• Special heat treat process results in a very malleable wire called Dead Soft Annealed (DSA)

• Copper permanently bonded to the steel core prevents corrosive of the steel core.

• Very little scrap value, discouraging theft and leaving the grounding system intact

• Compliant with IEEE 80, ASTM B258, ASTM B910/B910M, ASTM B339, ASTM B227

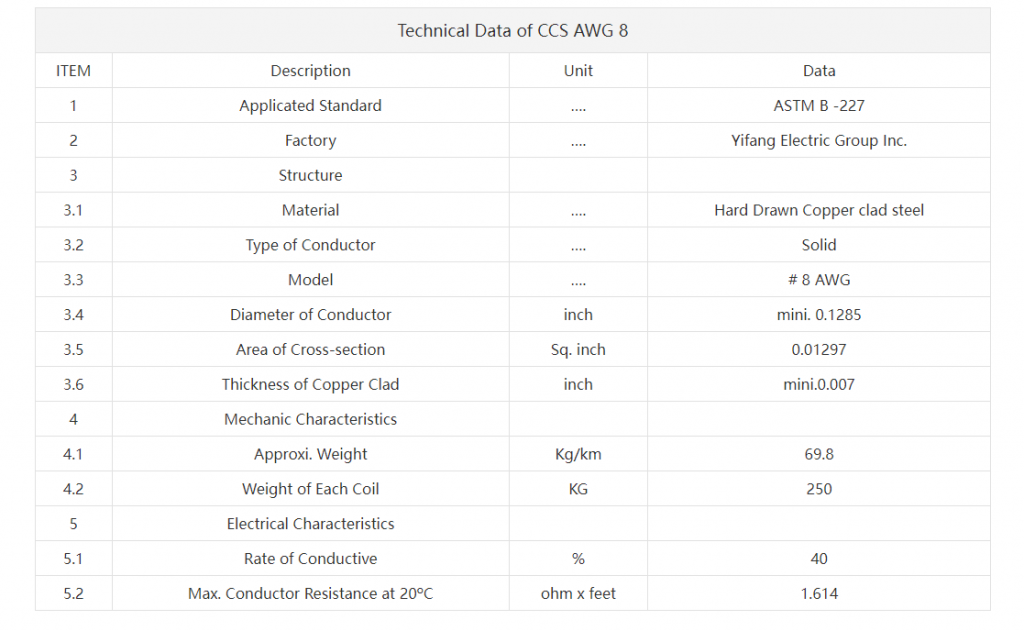

SPECIFICATION