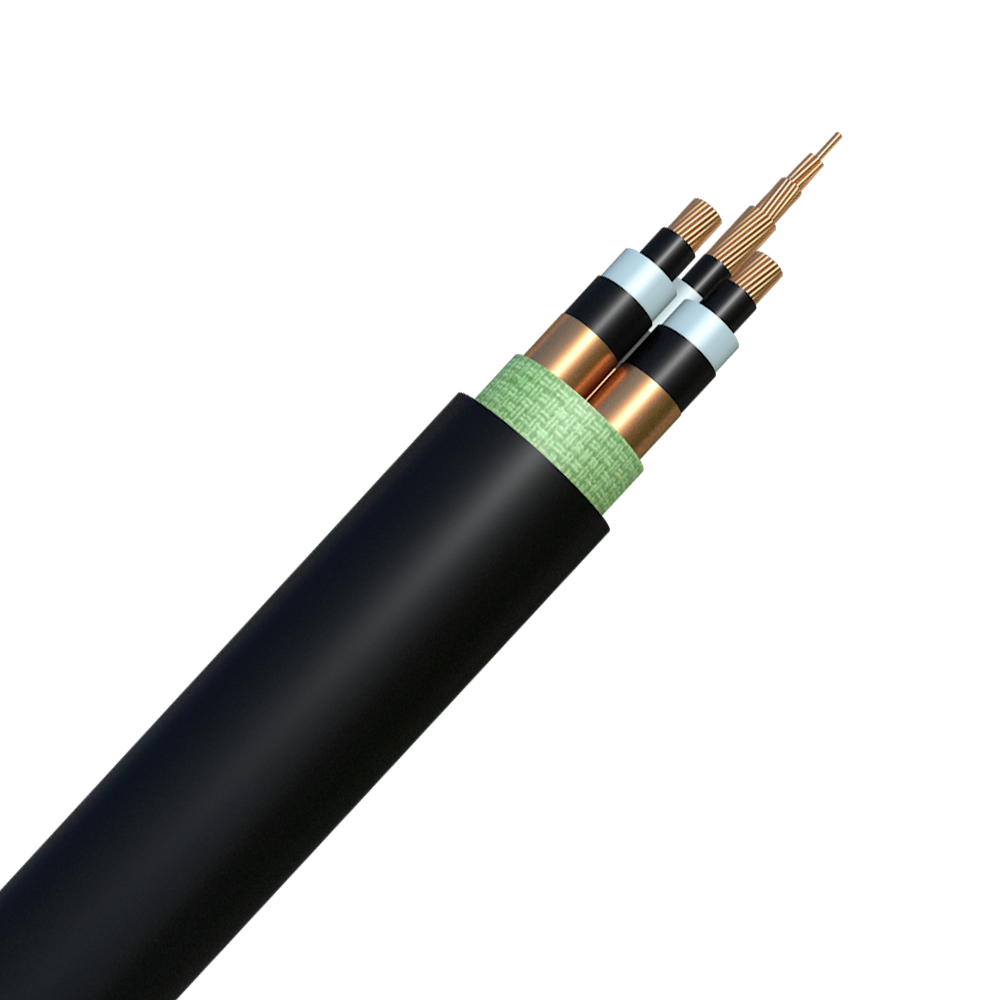

Shielded crosslinked polyethylene insulated cable are used for the transmission and distribution of electrical energy for normal conditions of installation and service, either indoors, outdoors, aerial, underground, or submarine in primary power and distribution circuits in industrial, commercial and power circuit of 5000V to 46000V.

Cables with water blocking conductor and water blocking tapes, are specially designed to be installed in high humid installations.

Features

Compared with paper insulated cables and PVC insulated cables, XLPE insulated cables have excellent electrical properties, mechanical properties, heat aging resistance, environmental stress resistance and chemical corrosion resistance, and are simple in structure and easy to use. , not restricted by laying drop, high long-term working temperature (90°C) and other advantages.

Application

Cables are used for a wide variety of industrial and utility applications. These cables are suitable for use in wet or dry locations and may be installed for direct buried, duct etc. Conductor temperature of operating is 90℃ for normal operation, 130℃ for emergency overload conditions and 250℃ for short circuit conditions.

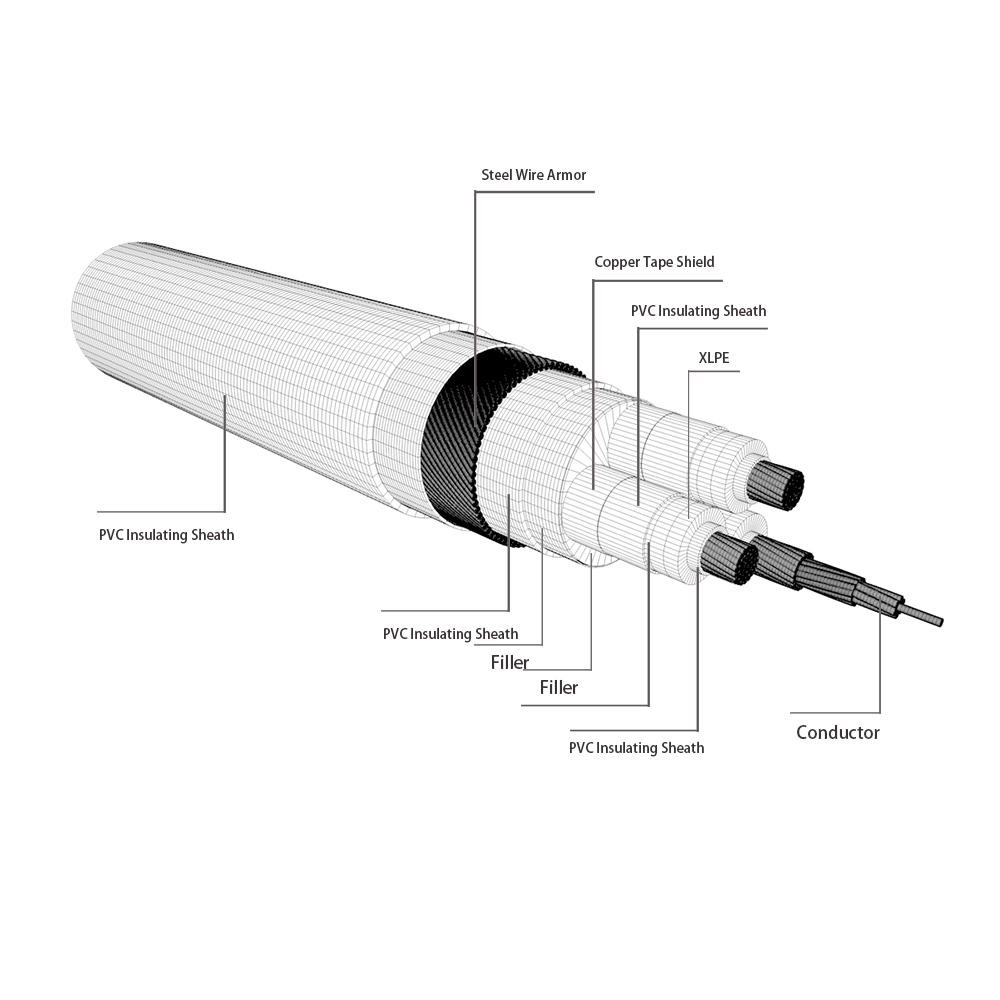

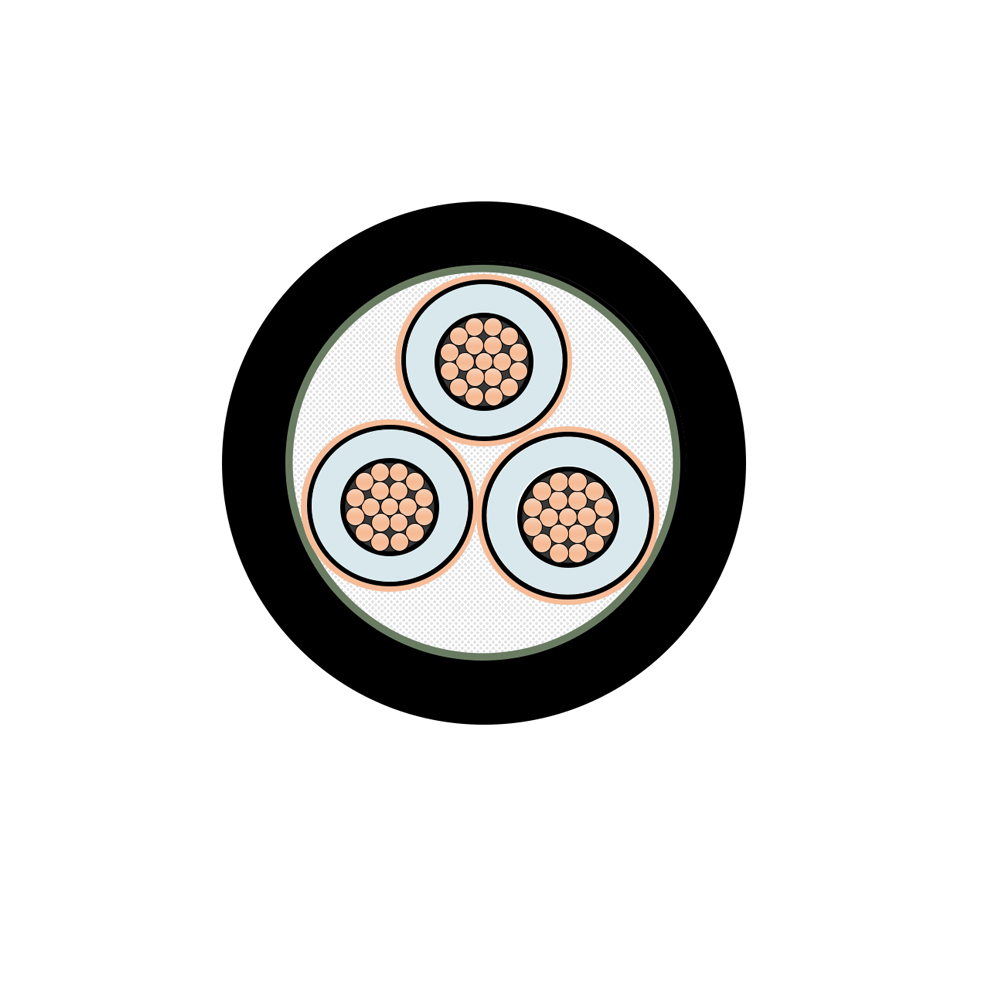

Construction

- Conductor

Annealed compact or compressed stranded bare copper per ICEA S-639 and S-682. - Conductor Shield

Extruded semiconductor thermosetting compounds that are applied directly to a conductor. It shall be free-striping from the conductor and be uniformly and firmly bonded to the insulation. - Insulation

90°C rated Cross-linked Polyethylene (XLPE) per ICEA S-93-639, ICEA S-682. - Insulation Shield

The extruded semiconductor copolymer compound is applied directly to the insulation.Conductor shielding, insulation and insulation shielding are used in series at one time. - Metallic Shield

Bare copper tape or bare annealed copper wires shielded. - Jacket

Black polyvinyl chloride (PVC) or polyethylene (LDPE LLDPE MDPE HDPE).