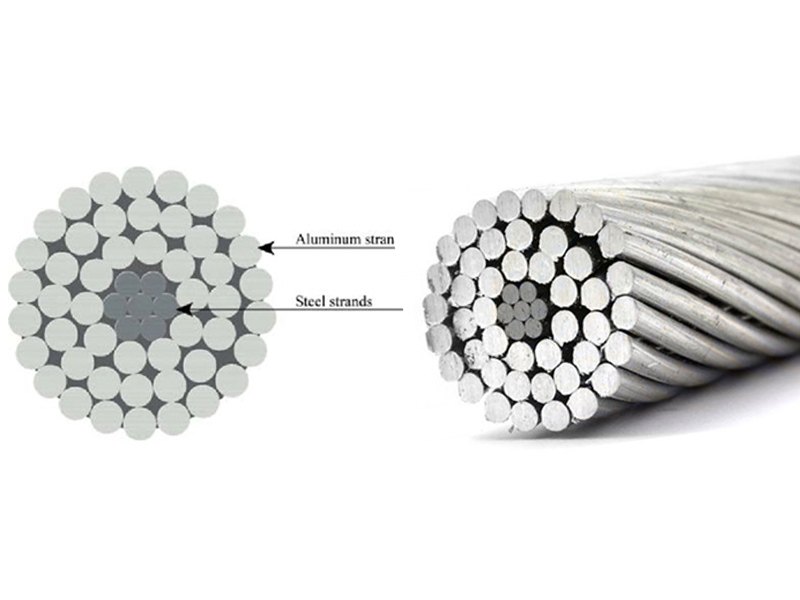

ACSR conductor is one of the main products of overhead conductors. Its steel core and aluminum strand share the conductor tension. In actual work, the steel core mainly plays the role of increasing the strength, and the aluminum stranded wire mainly plays the role of transmitting electric energy.

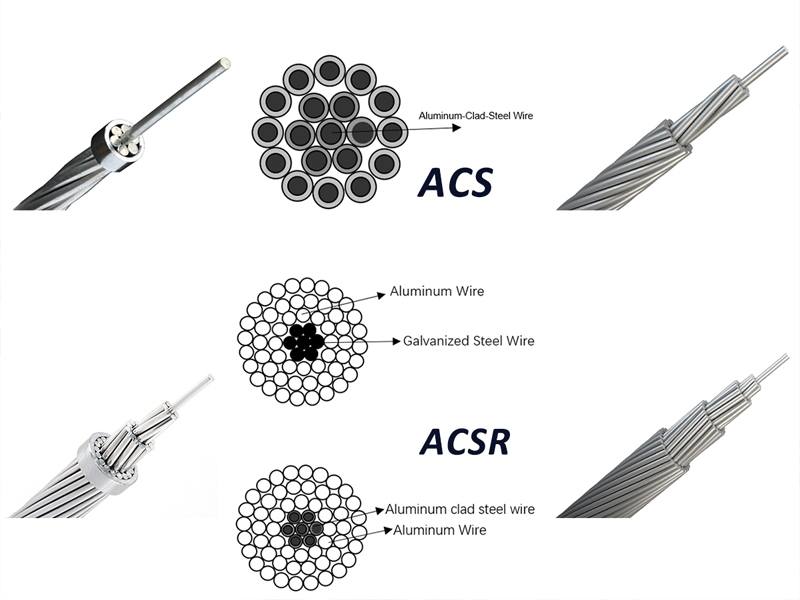

ACSR conductor is a combined stranded wire widely used in domestic EHV and UHV transmission lines. Its core is galvanized steel wire and the outer layer is stranded electrical round aluminum wire. The inner layer of the ACSR conductor is made of high-strength steel core, and the outer layer is made of duralumin, which comprehensively utilizes the advantages of high electrical conductivity of aluminum and high strength and light weight of the steel core.

ACSR conductor features:

ACSR is a more complex structure, which is made by winding multiple strands. The characteristics of strand structure can be reflected by its own parameters.

The wires are steel core and aluminum strands from the inside to the outside. The strands are tightly wound on the outside of the steel core at a certain helix angle, and the strands of the adjacent strands have opposite helical directions, so as to offset the unidirectional twisting effect of the twisted wires caused by the same direction winding. Each layer has a different number and diameter of strands.

ACSR conductor structure performance:

Steel cored aluminum stranded wire can be divided into inner layer and outer layer from the structure. The inner layer (core wire) is single-strand or multi-strand galvanized steel strand, which mainly bears the tension and the outer layer is single-layer or multi-layer duralumin strand, which mainly plays a conductive role. Under load, the wire mainly produces axial tensile stress, bending stress and torsional shear stress. The mechanical properties of the wire strands will have a decisive impact on the mechanical properties of the entire wire. When the wire is subjected to axial load or bending, the stress distribution between the wire strands is also different due to the different lengths and spatial helical shapes of the wires.

ACSR conductor electrical performance:

Steel-cored aluminum stranded wire has low resistance loss, energy saving and environmental protection. By reducing the DC resistance of the wires, improving the conductivity of the wires, and reducing transmission losses, the energy-saving effect is achieved.

Mechanical properties of ACSR conductor:

- Wire sag characteristics. Compared with the sag of ordinary aluminum stranded wire, the sag characteristics of different wires are different. The sag of the steel-reinforced aluminum stranded wire is slightly smaller (about 0.05 m) at a span of 500 m, which basically has no effect on the alignment of the towers, and the construction of the whole line of towers has not increased.

- The installation and construction are convenient, and the construction technology is the same as traditional wires.

- The rated tensile force of the steel-cored aluminum stranded wire is the same as ordinary wires, and has no effect on the load of the tower. Therefore, when using ACSR, the 750 kV general-purpose tower type can be used, which avoids repeated design, reduces engineering cost, and improves the standardization of line design at the same time.

Click to check More details

ACSR VS ACAR

- Low loss

The DC resistance of AAAC conductor is 3% smaller than ACSR conductor. At the same time, AAAC conductor can avoid the power loss caused by the hysteresis loss and the eddy current loss, which has a positive significance for the energy saving and consumption reduction of the transmission line. - Large delivery capacity

Compared with ACSR conductor, the AAAC conductor has an aluminum alloy stranded wire core, which can have both mechanical and conductive properties. So its transmission capacity is improved compared with ACSR conductor, enhancing the scalability of the line. - Corrosion resistance.

AAAC conductor can effectively avoid the galvanic corrosion problem between the aluminum wire of ACSR conductor and the galvanized steel wire, so as to increase the operating life of the wire, and improve the life span of the wire. - The icing overload capacity of AAAC conductor is basically the same as ACSR conductor.

Click to check ACSR VS AAAC

Epilogue

ACSR conductor can effectively reduce the running loss of the line and increase the transmission capacity of the line without greatly increasing the project investment. And it has excellent corrosion resistance of wires, so it has wide application prospects.