Crosslinked polyethylene (XLPE) insulated armored power cables are suitable for fixed laying in transmission and distribution lines with AC 50Hz and rated voltage from 0.6/1 (1.2)kV to 18/30(36)kV or in industrial installations.

The conductor of the cable may be copper or aluminum or aluminum alloy. The number of cores can be 1, 2, 3, as well as 4 and 5 (4 and 5 are usually low-voltage cables).

The armoring of the cable can be divided into steel wire armoring and steel tape armoring, and the non-magnetic armoring material used in the single-core AC cable.

According to the product suitable for the occasion, XLPE insulated power cable can be flame retardant type, fire resistant type, cold resistant type. Flame retardant cables include bunches of burning A, B, C, D, as well as low smoke halogen-free flame retardant cable series.

Long-term admissible operating temperature of conductor: 90℃. The maximum insulation temperature of XLPE shall not exceed 250℃ during short circuit (5S maximum duration).

The laying temperature of the cable should not be lower than 0℃.

XLPE power cable products can be produced according to IEC60502, BS 5467, BS 6622, HD 603, HD620, ICEA S 95-658, ICEA S-93-639, AS/NZS 5000, AS/NZS 1429, GB12706 and other product standards.

Features

Compared with paper insulated cable and polyvinyl chloride insulated cable, crosslinked polyethylene insulated cable has excellent electrical properties, mechanical properties, heat aging properties, environmental stress resistance and chemical corrosion resistance, and simple structure, easy to use, not limited by laying drop, long-term working temperature is high (90℃) and other advantages.

Application

XLPE insulated power cables are suitable for fixed laying on AC 50Hz, rated voltage 0.6/1 (1.2) kV to 18/30 (36) kV transmission and distribution lines.It is used to transmit electric energy.

Construction

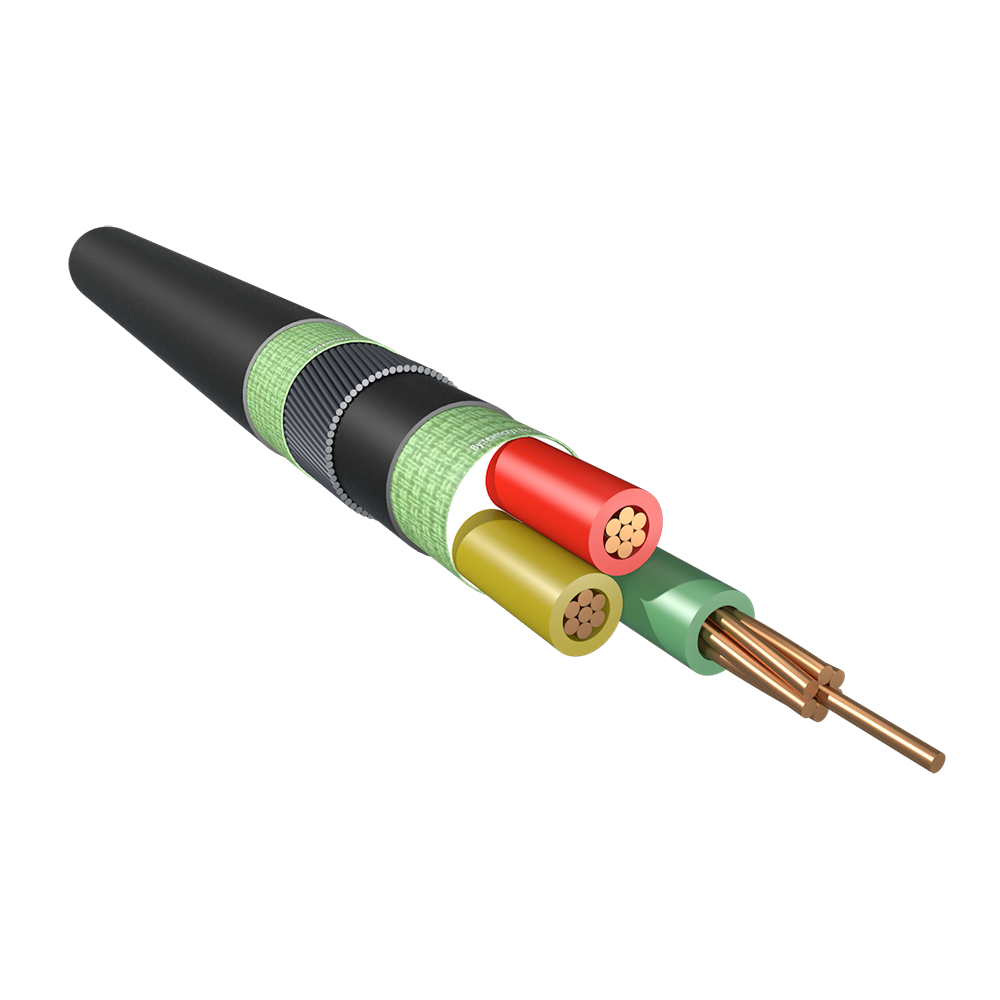

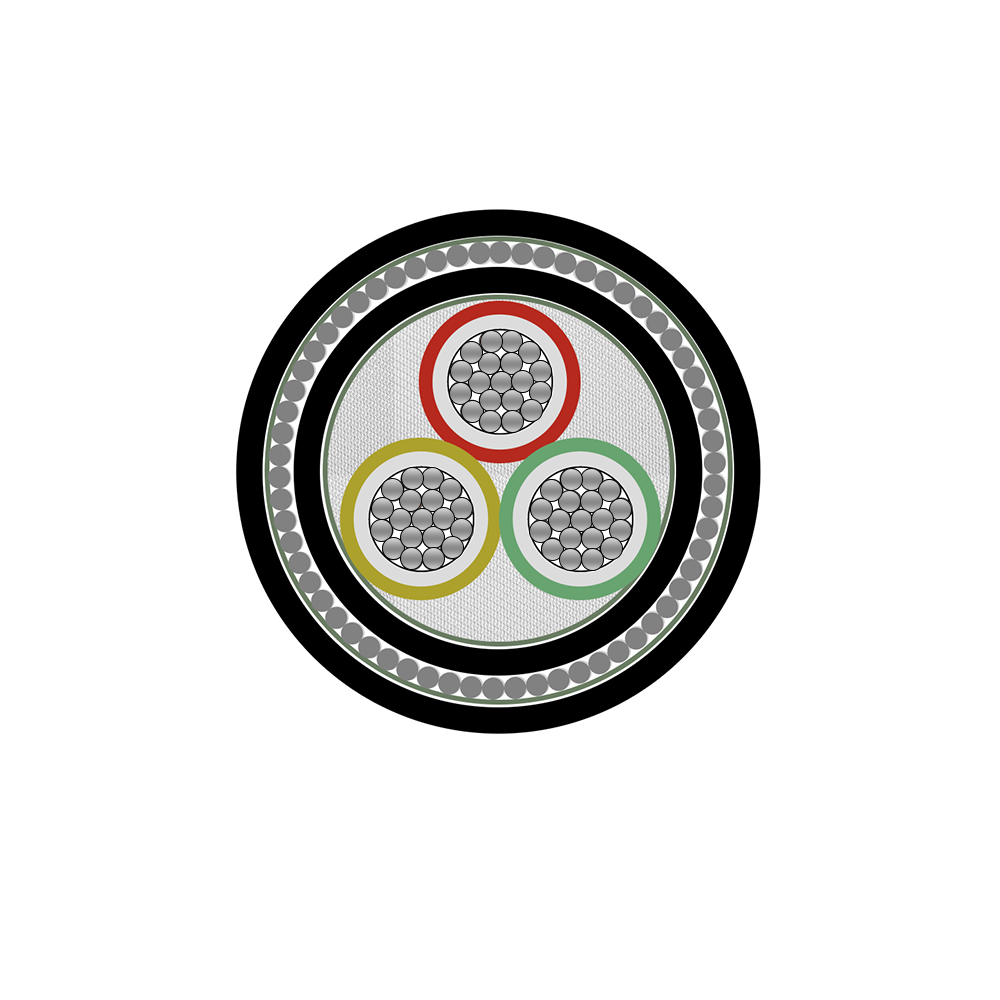

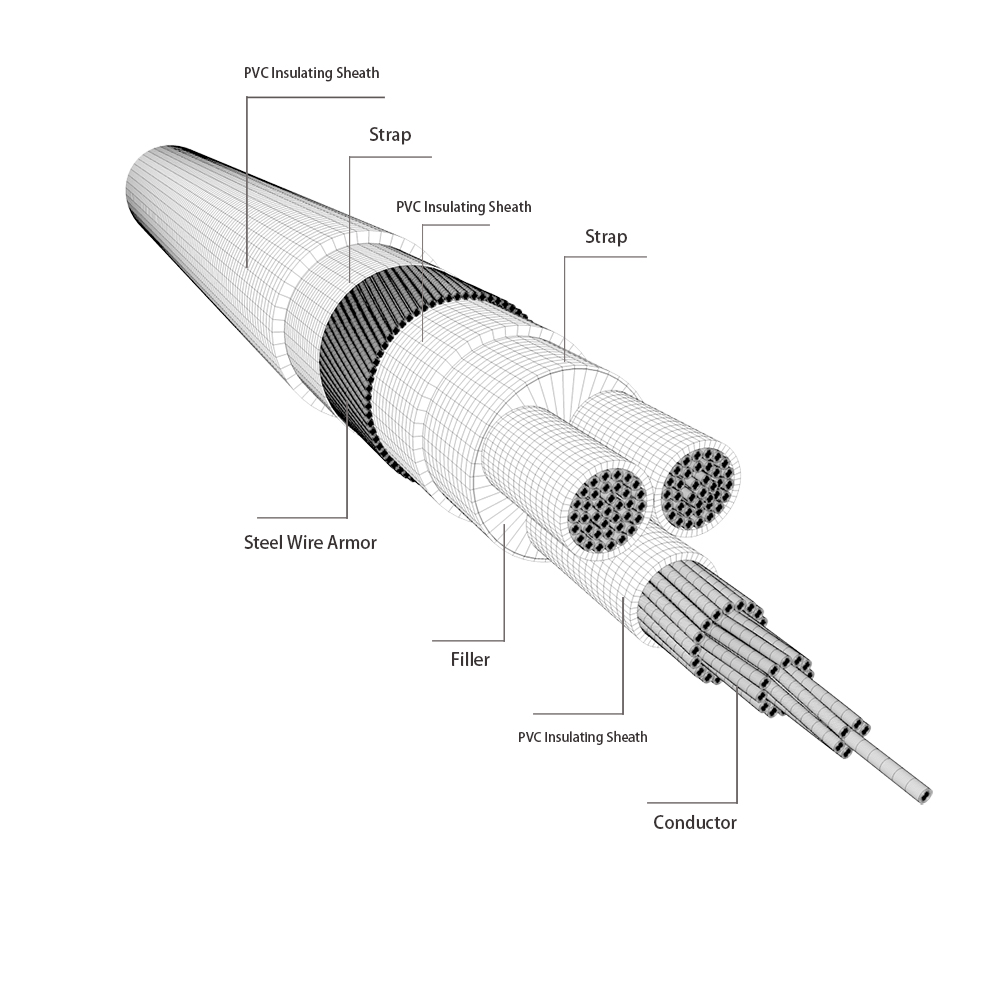

- Conductor

The conductor of the cable is made of pure copper, aluminum and aluminum alloy. Cable conductor adopts solid core conductor, circular stranded conductor, circular compacted conductor and sector conductor. - Insulation and semi-conductive shielding

The insulation consists of an extruded XLPE. Insulation is usually extruded outside the conductor. When the voltage is higher than 2000V, there is usually a semi-conductive layer outside the conductor, and the insulation shield is extruded outside the insulation. - Metal shield

Usually copper tape, copper wire. Also can use metal concentric layer, metal wire and metal belt combination structure. - Packed cable

Multi-core cables are formed with appropriate filler and cable core to make the cable circular. The entire cable core is usually wrapped with appropriate straps. - Metal armor

Wire armor is generally composed of galvanized round steel wire. The cable can withstand mechanical pressure and considerable tension. It is suitable for laying in vertical shafts, underwater and with drop or vertical conditions.

Metal tape armor is generally composed of galvanized steel tape, cable can withstand a certain external mechanical impact and radial pressure.

Armor of single-core cables used in AC systems shall be made of non-magnetic metal materials.

Sheathed with extruded PVC or PE isolation sheath is the cushion layer. The low voltage cable shall have extruded or overlapped liner (if permitted by standard). - Outer sheath

The outer sheath of the cable is usually composed of PVC and PE. LSOH material should be used for halogen-free low-smoke flame-retardant cables. Sheath thickness in line with the corresponding product standards. The outer sheath is generally black except for special requirements.