In the HD603 standard,XLPE insulated power cables are included, which are suitable for use on public distribution lines of underground AC rated voltage distribution systems of 0.6/1 kV and below. When the cable is used in a DC system, the voltage to ground shall not exceed 1.8kV.

The conductor of the cable can be copper or aluminum and aluminum alloy, and conform to the regulations of HD383. The number of cores can be 1 core, 2 cores, 3 cores, 4 cores, 5 cores.

According to the suitable occasion of the product, XLPE insulated power cables can be flame-retardant, low-smoke, halogen-free and flame-retardant cables.

The long-term allowable working temperature of the cable conductor: 90°C.

Features

Compared with PVC insulated cables, XLPE insulated cables have better electrical properties, mechanical properties, and heat aging resistance. Simple structure, easy to use, high long-term working temperature (90°C), etc.

Application

XLPE insulated power cables are suitable for fixed laying on distribution lines with AC 50Hz and rated voltages of 1 kV and below, and are used to transmit electric energy.

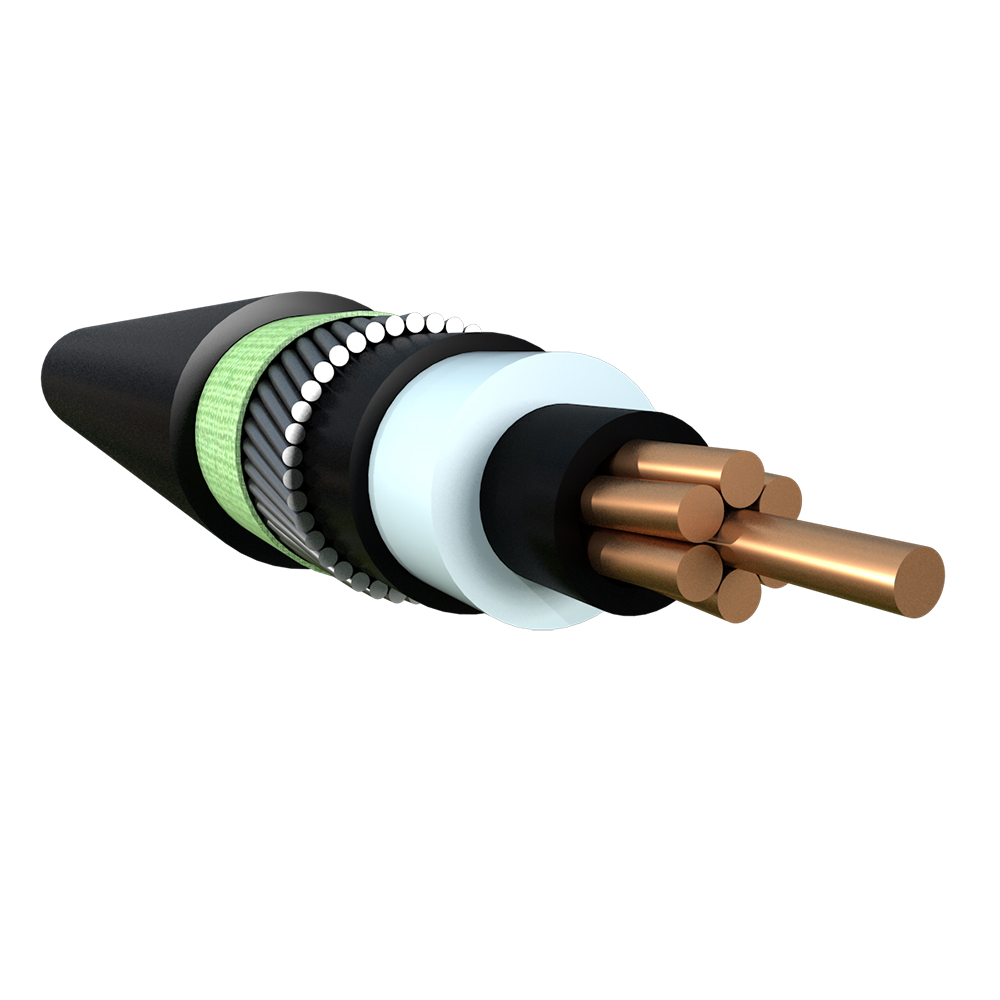

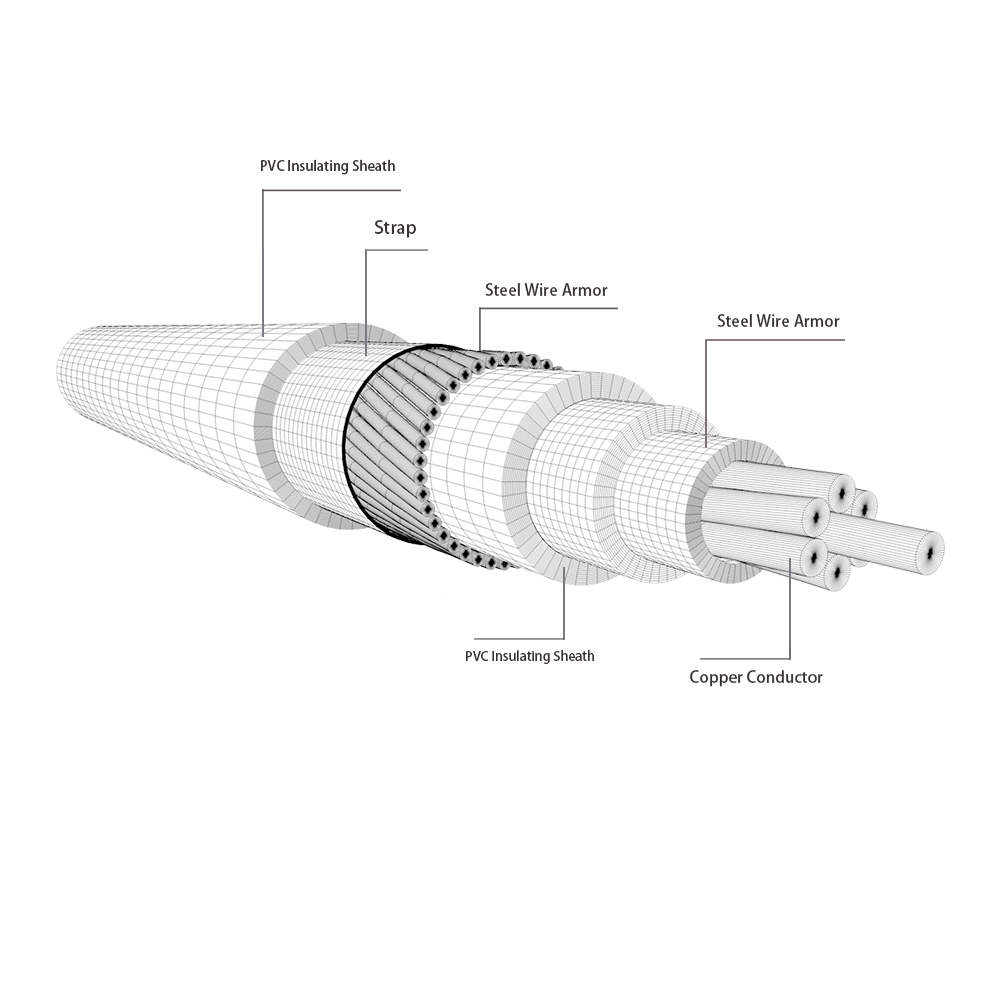

Construction

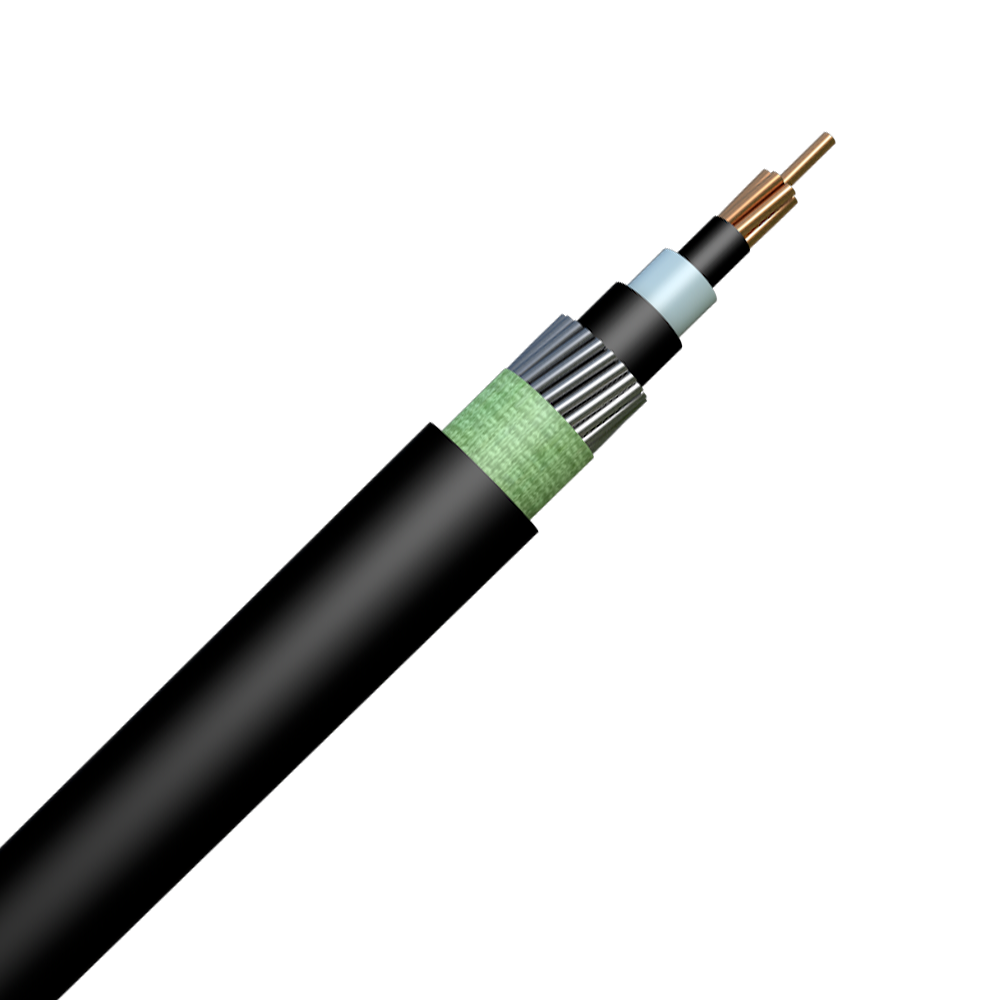

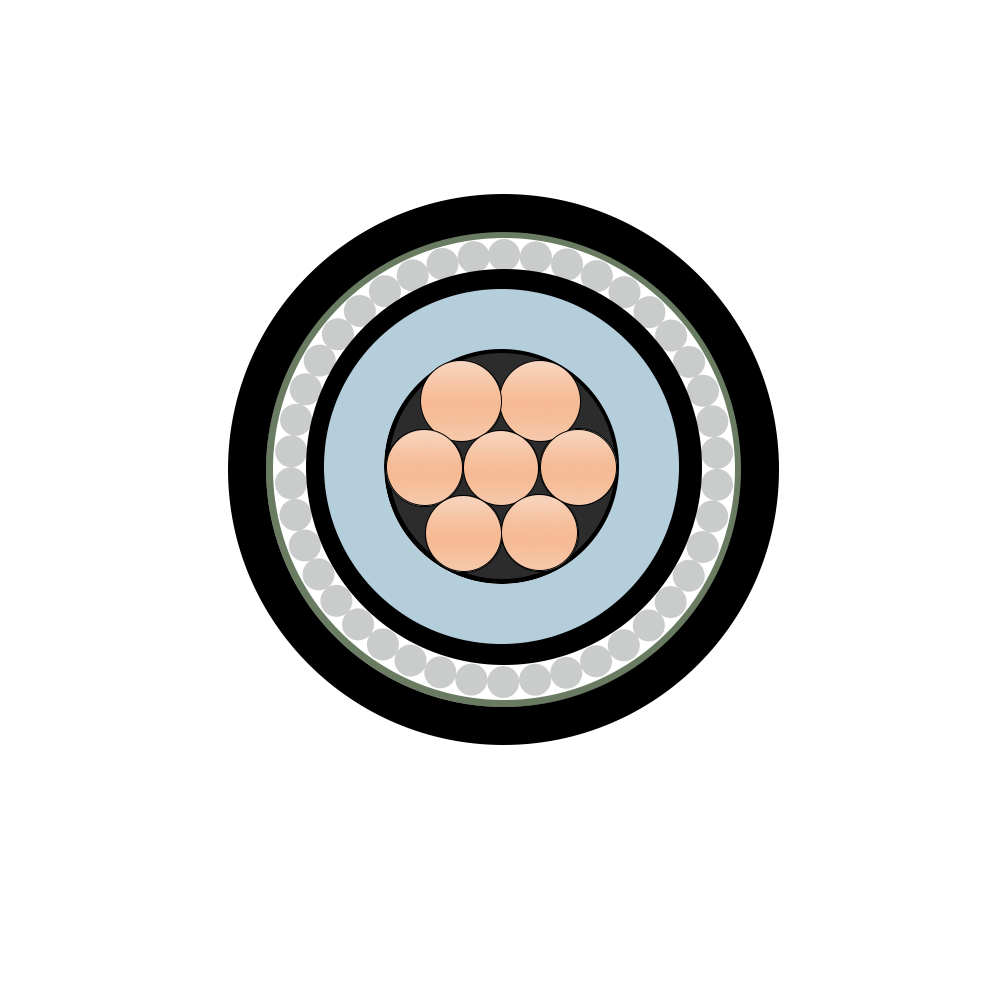

- Conductor

The cable conductor material is composed of annealed copper, aluminum and aluminum alloy. The shape of the conductor can be circular or fan-shaped, and a solid conductor or a stranded conductor can be used. - Insulation

The insulation consists of extruded XLPE. - Cabled

Multi-core cables are cabled with the cores using appropriate fillers to make the cable round. - Concentric Conductor

Some cables have one layer of concentric conductors. - Outer Sheath

The outer sheath of the cable is composed of PVC or PE. Low-smoke halogen-free cables use halogen-free flame-retardant compound.