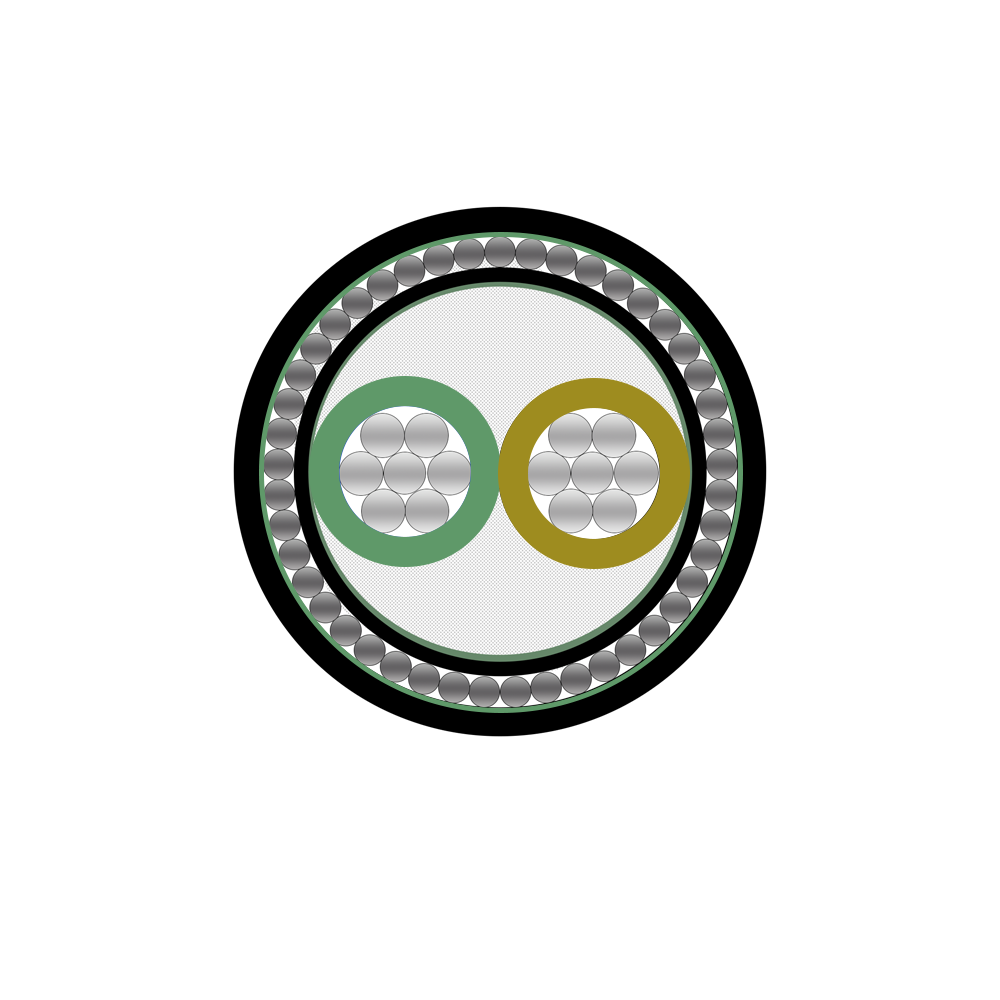

The conductor of the cable may be copper or aluminum or aluminum alloy. The number of cores can be single core, two core, three core, four core (including four core cross-sections and "Three big and one small" type with a small cross-section neutral core), five core (including five-core cross-sections,"Three big and two small" type with two small-section neutral wire cores,"Four big and one small" type with a small cross-section ground core).

The armor of cables can be divided into steel wire armor and steel tape armor, as well as non-magnetic armor materials used in single-core AC cables.

According to the suitable occasion of the product, PVC insulated power cables can be flame-retardant, fire-resistant, cold-resistant, etc. Flame-retardant cables include bundled combustion A, B, C, D types, and low-smoke, low-halogen flame-retardant and other series of cables.

The long-term allowable working temperature of the cable conductor: 70°C. When short-circuited (the longest duration is 5S), the maximum temperature of the PVC insulation shall not exceed 160°C.

The laying temperature of the cables should not be lower than 0°C.

PVC insulated power cables can be produced according to IEC60502, BS 6346, HD 603, ICEA S 95-658 AS/NZS 5000, CSA C22.2 NO.51, GB12706 and other product standards.

Features

Polyvinyl chloride insulated power cable has good chemical stability, acid, alkali, oil and organic solvent resistance, and has the characteristics of fire resistance. Good bending performance, easy installation and maintenance.

Application

Polyvinyl Chloride insulated power cables are suitable for fixed laying on distribution lines with AC 50Hz and rated voltages of 1 kV and below to transmit electric energy.

Construction

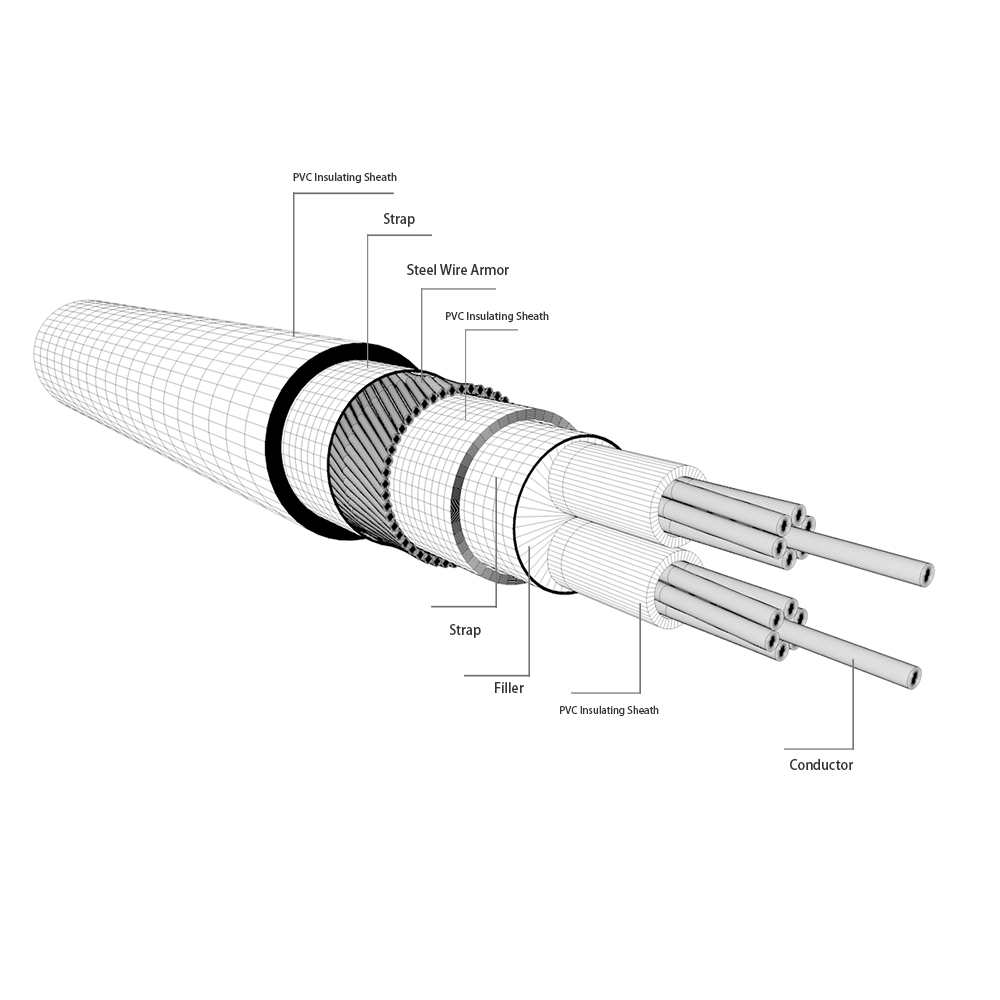

- Conductor

The cable conductor material is composed of pure copper, aluminum and aluminum alloy. The cable conductors are solid core conductors, round stranded conductors, round compact conductors and fan-shaped conductors. - Insulation

The insulation consists of extruded PVC. The insulation is extruded outside the conductor, and the insulation thickness complies with the corresponding standards. - Packed cable

Multi-core cables are cabled with the cores using appropriate fillers to make the cable round. The entire cabled core is usually properly taped. - Metal armor

Metal wire armor is generally composed of galvanized round steel wire. The cable can withstand mechanical pressure and considerable tension. It is suitable for laying in vertical shafts, underwater and with drop or vertical conditions.

The metal tape armor is generally composed of galvanized steel tape, and the cable can withstand the impact and radial pressure of a certain mechanical external force.

Under the armor, the insulating sheath with extruded PVC or PE is used as the cushion layer, or the inner lining layer with overlapping wrapping is used. - Outer sheath

The cable outer sheath is composed of PVC. The thickness of the sheath complies with the relevant product standards. The outer sheath is generally black unless otherwise specified.