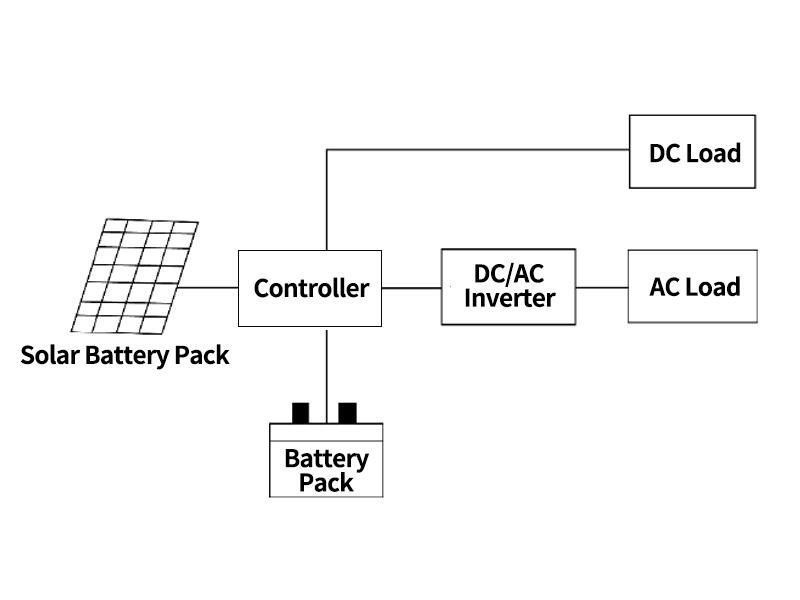

Solar cables, also known as solar photovoltaic cables (PV cables), are energy transmission components in photovoltaic power generation systems and play a vital role in photovoltaic power generation components. Nowadays, it has become a trend to use solar photovoltaic cables in photovoltaic power generation systems.

Solar cables mainly include three categories:

- The power cable connecting solar power generation components and transmitting electric energy. Its rated voltage U0/U is 600 V/1 000 V for AC and 1800 V for DC. The number of cores is 1-5 cores, and the nominal cross-section is 1.5 mm2-240 mm2. Among them, single-core power cables connected to solar power generation components are used more.

- Control cables for photovoltaic power generation systems used in control circuits, monitoring circuits and protection circuits of 450 V/750 V and below. Its number of cores is 2-6 cores, and the nominal cross-section is 0.75 mm2-10 mm2.

- Signal cable used for 300 V/500 V electronic computer system, monitoring loop, signal transmission and instrument testing of automatic control system, and instrument connection. Its nominal cross-section is 0.75 mm2-2.5 mm2, which can be twisted pair, triple wire or quadruple wire.

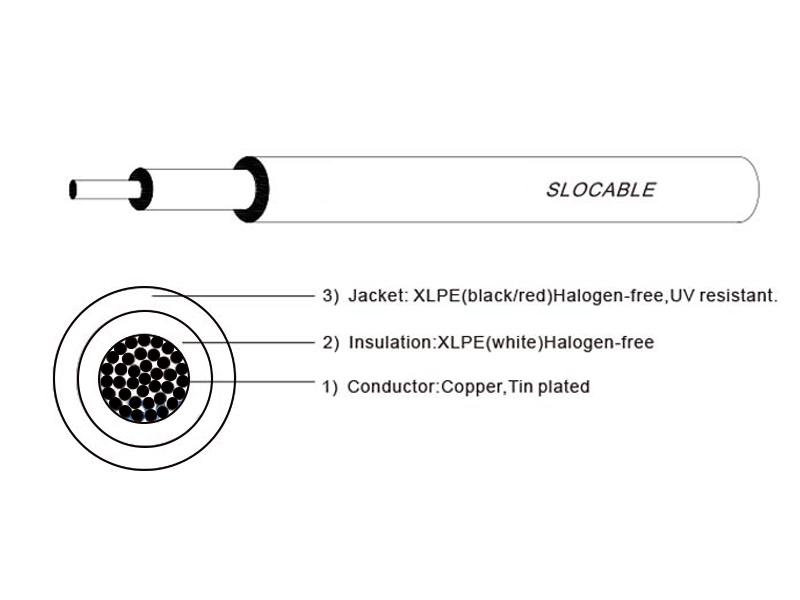

Structure of Solar Cable

Since there is no IEC international standard for solar cables, the standard requirements of each country are different. At present, more companies adopt the European standard EN 50618: 2014 "Electric cab-bles for photovoltaicsystems". The photovoltaic cable structure is introduced below in combination with the European standard.

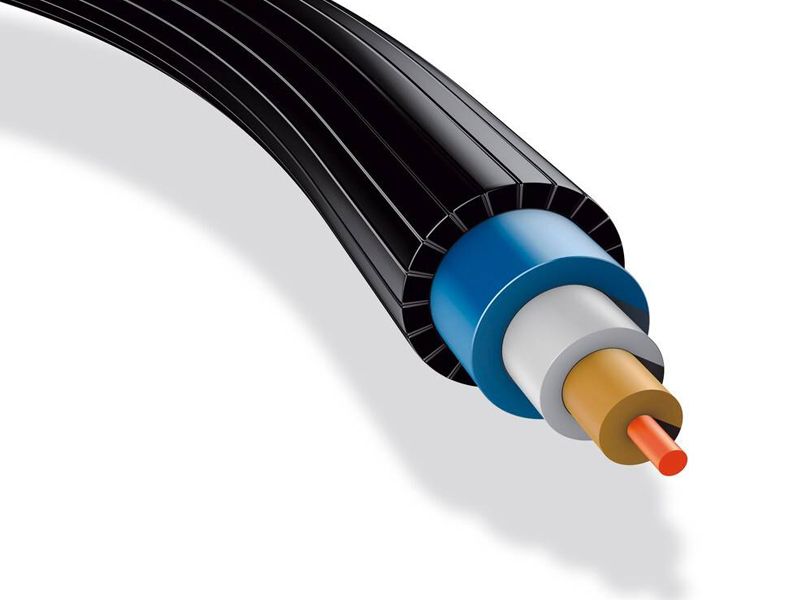

The conductor of the single-core power cable is composed of tinned annealed copper wire. The conductor is stranded in a regular way, and the conductor is extruded with a layer of anti-ozone and uv-resistant radiation cross-linked low-smoke halogen-free flame-retardant polyolefin insulation material, and then a special sheath for photovoltaic cables is extruded outside the insulation. Photovoltaic cables with tensile and compressive requirements can be added with armor layers such as metal tapes and wires, and can also be made into special photovoltaic cables with anti-rodent and anti-ant functions.

Structure dimensions and technical parameters of single-core photovoltaic power cables:

| Conductor cross section/ mm² | Number of conductors | Conductor diameter/mm | Insulation Thickness/ mm | Sheath thickness/ tnm | Cable outer diameter upper limit/mm | Minimum insulation resistance at 20°C/MΩ-km | Minimum insulation resistance at 90°C/ MΩ-km |

| 1.5 | 30 | 0.25 | 0.7 | 0.8 | 35.4 | 860 | 0.86 |

| 2.5 | 49 | 0.25 | 0.7 | 0.8 | 5.9 | 690 | 0.69 |

| 4 | 56 | 0.3 | 0.7 | 0.8 | 6.6 | 580 | 0.58 |

| 6 | 84 | 0.3 | 0.7 | 0.8 | 7.4 | 500 | 0.50 |

| 10 | 84 | 0.4 | 0.7 | 0.8 | 8.8 | 420 | 0.42 |

| 16 | 126 | 0.4 | 0.7 | 0,9 | 10.1 | 340 | 0.34 |

| 35 | 276 | 0.4 | 0.9 | 1.1 | 14.0 | 290 | 0.29 |

| 120 | 608 | 0.50 | 1.2 | 1.3 | 22.8 | 210 | 0.21 |

| 240 | 1221 | 0.50 | 1.7 | 1.7 | 32.1 | 200 | 0.20 |

The control cables used in the power generation system are equipped with metal shielding layers in the control circuit, monitoring circuit and protection circuit, which can effectively prevent the interference of the surrounding electromagnetic field. Shielding forms include copper tape wrapping shielding, copper wire braided shielding, aluminum-plastic composite tape wrapping shielding, etc.

In order to reduce the mutual interference between the loops and the interference of the external electromagnetic field, the signal cables used for the signal transmission of the electronic computer system, the monitoring loop, and the automatic control system, as well as the signal cables used for the connection of the detection instrument and the instrument have increased the requirements for the separate shielding and total shielding of the cable. There are specific requirements for the performance of the cable's working capacitance, capacitance unbalance value, and shielding suppression coefficient.

Use of solar power cables

Although solar power generation has incomparable advantages, the intensity of the sun is affected by various factors (season, climate, location, etc.) .Energy can not maintain a constant. That is, solar energy is a kind of radiant energy, which has timeliness. It must be converted into other forms of energy in time to store and utilize it. Cables as transmission elements have become an indispensable component in photovoltaic power generation systems.

Performance of solar cables

Solar cables are exposed to the external natural environment for a long time. Cables are not only irradiated by strong ultraviolet light from the sun, but also used in hot, cold, humid and polluted places (such as dust, salt spray in coastal areas, chemical pollution in industrial areas, etc.). Whats more, It is required to withstand various mechanical external forces (such as gravity, traction, impact, and wind vibration, etc.). Therefore, there are strict standard assessment requirements for the performance of the cable.

- The temperature range of the photovoltaic cable is -40-90 °C, the maximum operating temperature of the conductor is 120 °C, and the allowable short-circuit temperature within 5 s is 200 °C.

- The bending radius of the cable is not less than 4 times the outer diameter of the cable.

- The insulation and sheath are made of low-smoke, halogen-free, flame-retardant, radiation cross-linked polyolefin materials.

- The designed service life of the cable meets the requirement of no less than 25a.

- The cable not only has excellent ozone resistance, acid and alkali resistance, ultraviolet resistance and salt spray corrosion resistance, but also can withstand a wider range of temperature changes.

Due to the special use environment of photovoltaic cables, a number of performance tests must be carried out before the cables leave the factory, including cable structure size inspection, conductor DC resistance test, finished product voltage test, insulation resistance test, insulation long-term DC resistance test, sheath surface resistance Test, insulation and sheath material performance test, low temperature test, ozone resistance test, sheath weather resistance test, dynamic penetration, damp heat test, thermal life test, acid and alkali resistance test, halogen-free smoke density test, flame retardant test, etc.

Reference ampacity of solar power cables

| Conductor cross section/ mm² | Carrying capacity under different laying methods/A | ||

| laying in the air | laying on the surface of the equipment | Laying adjacent to the surface of the equipment | |

| 1.5 | 30 | 29 | 24 |

| 2.5 | 41 | 39 | 33 |

| 4 | 55 | 52 | 44 |

| 6 | 70 | 67 | 57 |

| 10 | 98 | 93 | 79 |

| 16 | 132 | 125 | 107 |

| 35 | 218 | 207 | 176 |

| 120 | 488 | 464 | 390 |

| 240 | 775 | 736 | 620 |

Epilogue

As a renewable and clean energy, solar power generation does not emit harmful gases and pollute the atmospheric environment. It is clean and safe, and is developing rapidly around the world just like new energy sources such as wind energy, ocean energy, and geothermal energy.

Solar cables are used to connect electrical lines of solar power generation systems, and have excellent electrical and physical and mechanical properties. Photovoltaic cable products for various purposes will also be more and more used in photovoltaic power generation systems.