When selecting the best electrical cables suitable for outdoor use, there are a few factors to consider. This article will look at the characteristics that make electrical cables appropriate for outdoor use, as well as some of the aspects to consider when purchasing. The following factors make electrical cables suitable for outdoor use:

On the wires, the type of insulation used.

Electrical cables are typically made with three types of insulation: PVC, polyethylene, and cross-linked polyethylene. PVC is the most common type of insulation, as it is durable and resistant to sunlight and moisture.

However, PVC is not as flexible as polyethylene, making it less suitable for use in cold weather. Polyethylene is a more flexible alternative that is also resistant to moisture and chemicals. Cross-linked polyethylene is the most expensive type of insulation, but it is also the most durable and can withstand extreme temperatures.

When choosing an electrical cable for outdoor use, it is important to consider the environment in which it will be used. For example, if the cable will be exposed to sunlight, it is important to choose a cable with UV-resistant insulation. If the cable will be used in a wet or humid environment, it is important to choose a cable with water-resistant insulation.

The type of jacket or covering protecting the wires.

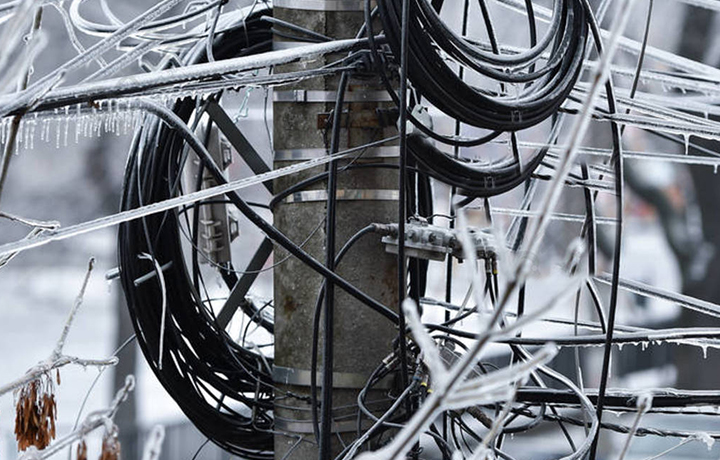

Electrical cables are used in a variety of settings, both indoors and out. While most applications don't require special considerations, those that will be exposed to the elements require a different type of cable. Outdoor electrical cables must withstand exposure to sunlight, moisture, and extreme temperatures.

They also need to be durable enough to resist abrasion, chewing, and other forms of damage. The type of jacket or covering protecting the wires makes electrical cables suitable for outdoor use. The most common materials used for outdoor cables are polyvinyl chloride (PVC) and polyethylene (PE).

PVC is more flexible than PE, making it easier to route through tight spaces. However, PE is more resistant to sunlight and chemicals, making it the better choice for buried applications. When selecting an outdoor electrical cable, it's important to consider the environment in which it will be used. This will ensure that the cable can withstand the elements and continue to perform as expected.

The gauge or thickness of the wire.

Most electrical cables are made of copper or aluminium wire, which is wrapped in plastic insulation. The gauge or thickness of the wire makes electrical cables suitable for outdoor use. In general, the thicker the wire, the lower the gauge number. AWG stands for American Wire Gauge, which measures the thickness of wire. As wire thickness increases, AWG decreases.The thicker the wire, the lower the AWG number.

For example, AWG 10 is thicker than AWG 12. Electrical cables are typically made with either solid or stranded wire. Stranded wire is made up of a group of thin wires that are twisted together to form a larger cable. Stranded wire is more flexible than solid wire and is less likely to break if it is bent.

Electrical cables are also rated by their voltage and amperage capacity. Voltage is a measure of the difference in electrical potential between two points, and amperage is a measure of the flow of electric current. Electrical cables that are used outdoors must be able to withstand higher voltages and amperages than those that are used indoors.

Outdoors, electrical cables are also exposed to weather conditions that can damage the insulation, so they must be able to withstand UV radiation, extreme temperatures, and moisture.

Whether the wire is stranded or solid.

Electrical cables are designed to carry an electrical current from one point to another. The wire conductor is the part of the cable that actually carries the current, and an insulating material surrounds it. The type of conductor (stranded or solid) and the type of insulation are what make a cable suitable for outdoor use. Stranded conductors are made up of a number of small wires twisted together.

They are more flexible than solid conductors and less likely to break if the cable is bent. This makes them ideal for applications where the cable needs to be routed through tight spaces. Solid conductors are made from a single piece of wire. They are more rigid than stranded conductors and can carry more current. However, they are also more likely to break if the cable is bent.

This makes them ideal for applications where the cable will not be subject to movement. The type of insulation is also important in determining whether a cable is suitable for outdoor use. Some types of insulation, such as PVC, degrade when exposed to sunlight and moisture. Other types, such as Teflon, are resistant to these conditions and can be used in outdoor applications.

The type of metal used in the conductor.

Electrical cables are made of metal, which is an excellent conductor of electricity. The type of metal used in the conductor can make a big difference in the cable's suitability for outdoor use. Copper is the most popular choice for electrical cables because it is very conductive and resistant to corrosion.

Aluminum is also a good choice for electrical cables, but it is not as conductive as copper and can oxidize over time. For this reason, aluminum cables are usually only used for short runs or in applications where corrosion resistance is more important than conductivity. Nickel-coated copper cables are also available, but they are more expensive than copper or aluminum cables.

If the cable is shielded.

Electricians have a saying: "Current always takes the path of least resistance." In other words, electrons will flow from the point of high voltage to a point of low voltage. This is why electrical cables must be shielded - to protect against interference from outside sources that could cause the current to "leak" out of the cable. Shielding also helps to protect against electromagnetic interference, or EMI, which can cause data loss and signal degradation.

Foil and braid are the two main types of shielding Foil shielding consists of a layer of aluminum foil that is wrapped around the cable. Braid shielding consists of a mesh of metal strands woven around the cable. Both types of shielding are effective, but braid shielding is more flexible and less likely to tear. Electricians typically use braid-shielded cable for outdoor applications.

The amount of current that the wire can handle..

The choice of electrical cable for any given application is vital. The amount of current that the wire can handle, what makes electrical cables suitable for outdoor use, and other factors must be considered to ensure safe and efficient operation. While there are many different types of electrical cable, some are better suited than others for outdoor use.

For example, cables that are made with PVC insulation are more durable and resistant to sunlight and moisture than those with rubber insulation. In addition, PVC-coated cables are also less likely to sustain damage from abrasion or impact. As a result, they are an excellent choice for applications where the cable will be exposed to the elements.

If it's underground, what kind of conduit is being used

Electrical cables are not all alike. The type of conduit used depends on where the cable will be installed. For example, insulated cables are used in dry locations, while cables that are jacketed with moisture-resistant materials are used in wet or damp locations.

Cables that will be buried underground must also be durable enough to withstand physical damage from rocks and other debris. In addition, the insulation on buried cables must be able to resist corrosion from soil and water. Electrical cables are designed to meet these various challenges to safely and reliably provide power to our homes and businesses.

Conclusion.

The process begins with insulation. A strong, tough material is placed around the inner cores of cable to shield them from the elements and impacts. Following that, it is time to add another outer cover. The jacket is comprised out of PVC or polyethylene, both of which are resistant to extreme temperatures, and chemicals.

In addition, the cable is bonded using special weatherproof connectors that form an encapsulated seal around the cores of the cable. The seal stops moisture from getting into the cable, ensuring it is an unreliable and secure connection.

Additionally, as weatherproofing offers an additional layer of protection, most manufacturers provide longer warranties on outdoor cables. If you ever need to wire your outdoor lighting or power a construction site, you can rest sure that there are many options to ensure your safety and stay connected.