SANS 1418 is one of the South African national standards for overhead bundled conductor systems for low, medium and high voltage distribution lines and transmission lines. The standard stipulates specific requirements for wire cores, installation and grounding, etc., to ensure good performance and reliability of power distribution lines.

Features

- Good insulation performance

- Good anti-corrosion performance

- Anti-external damage

- The strength meets the requirements.

It can solve the problems encountered in the operation of conventional bare wires, and the price is cheaper than buried cables

Application

It can be seen in many places, such as urban power grid transformation, road lighting and other lines.At the same time, it will also be used in places with more lightning, dense forests, and heavy smoke.

Construction

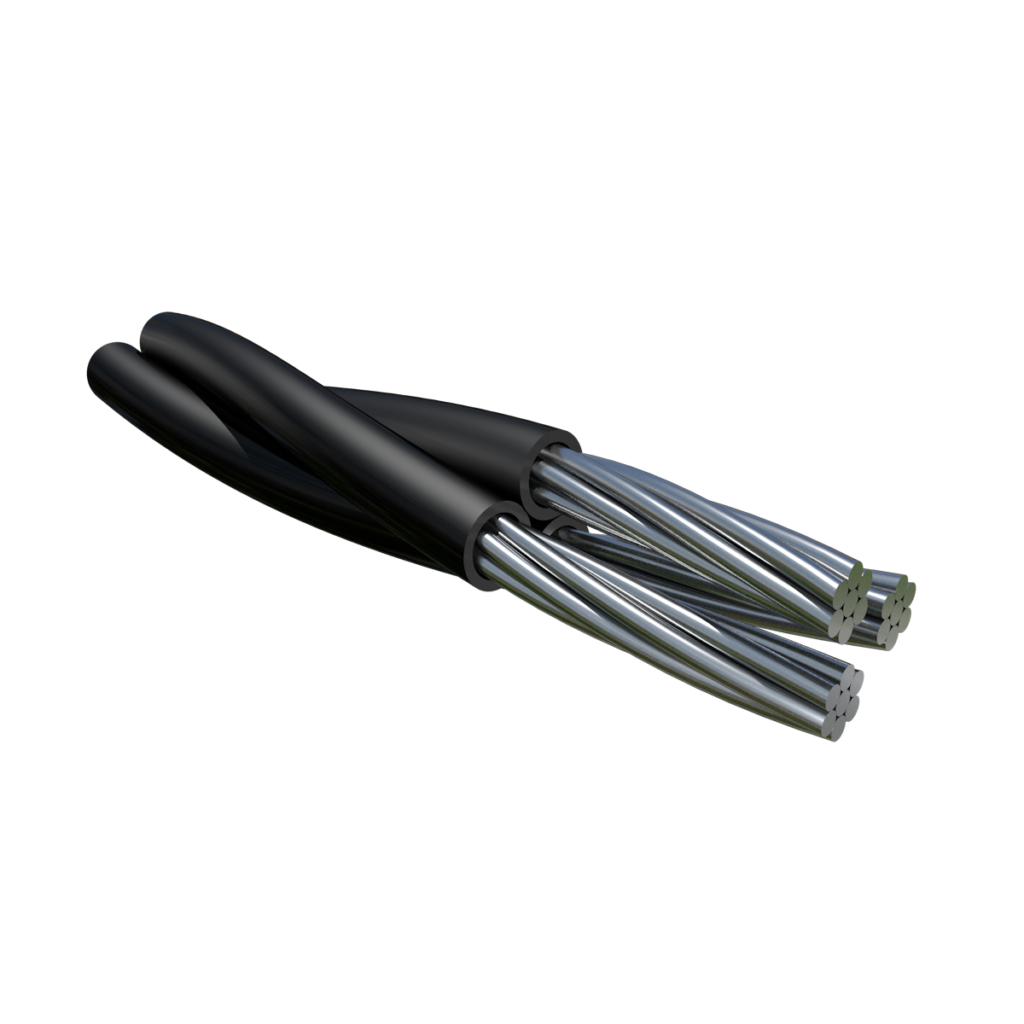

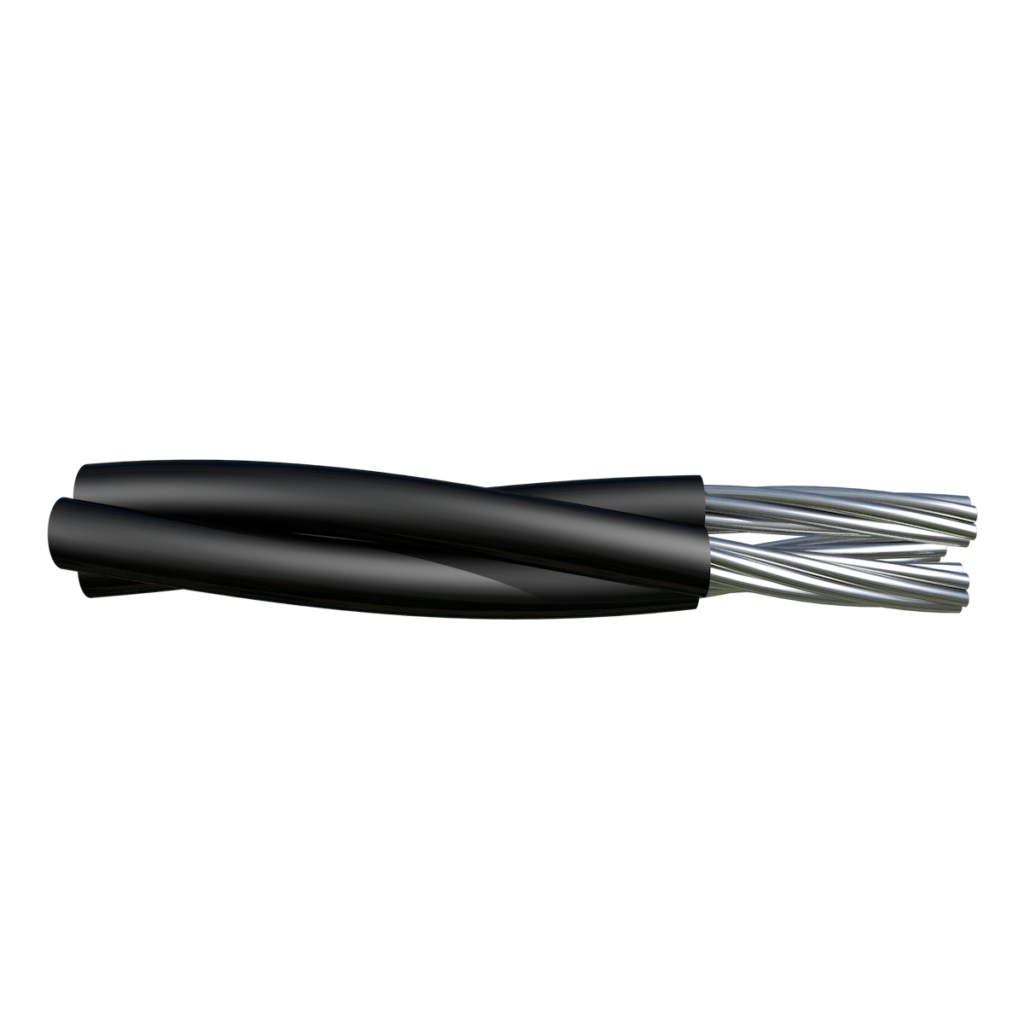

1.Conductor

The wire core has a circular cross-section. Bundled conductors with or without supporting cores, auxiliary cores or grounding cores or a combination of the above cores. The direction of the outermost stranding of the conductors is left

2.Insulation

The insulation consists of extruded XLPE.

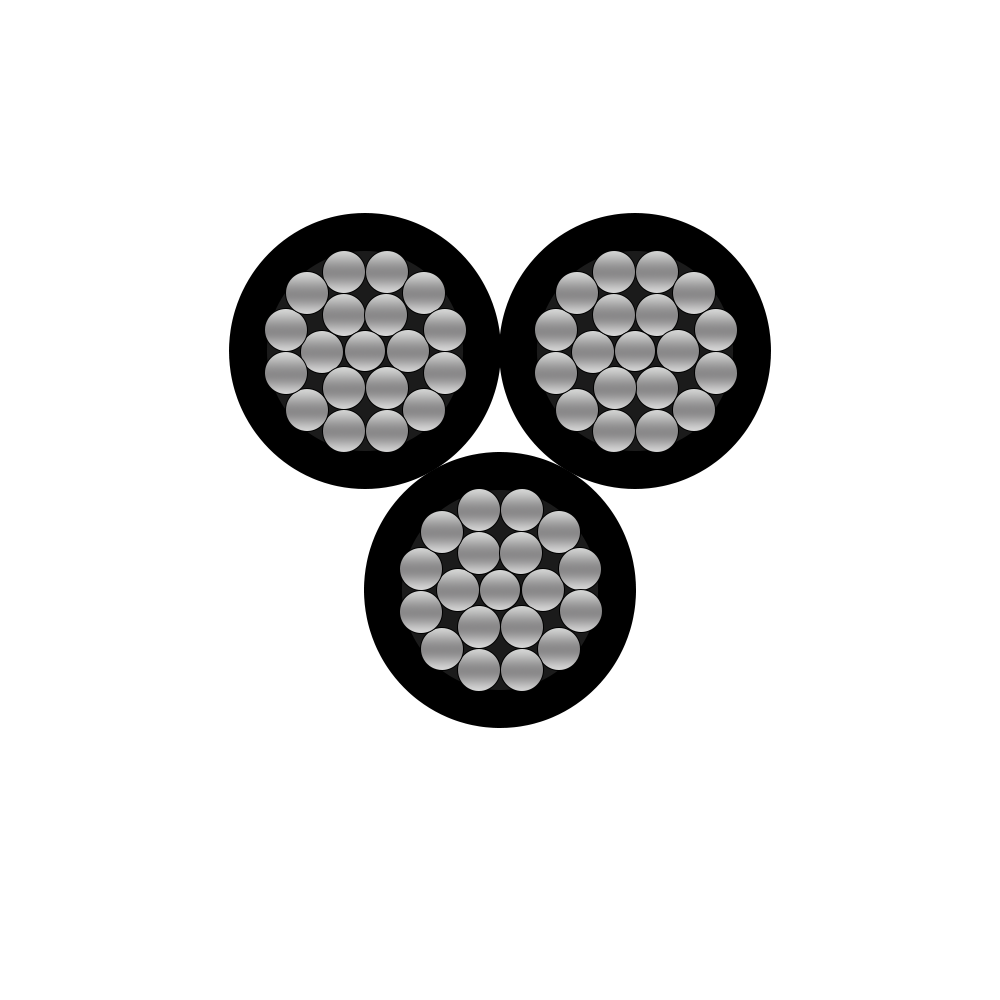

3.Cabling

Multi-core cables should be cabled, the cabled direction is left, and the cabled pitch ratio is 55-75 times. Bundled conductors with supporting cores shall consist of 4 cores of the same nominal cross-sectional area (for example, three phase cores plus one neutral core). Optionally add a 5th core as a ground conductor. The bundled conductors may also contain one or two auxiliary cores with a nominal cross-sectional area of at least 16 mm2; bundled conductors with supporting cores shall consist of at least three phase cores with the same nominal cross-sectional area, which The three phase cores should be cabled around the supporting core, and the supporting core should be kept straight during the whole cable forming process. An additional core with the same nominal cross-sectional area as the phase core can be optionally set as the neutral line. The bundled conductors may also include one or two auxiliary cores having a nominal cross-sectional area of at least 16 mm 2.

Performance

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Type of conductor or core | Nominal cross-sectional area mm2 | Number of wires mm | Resistance at 200C Ω/km Max | Diamater of conductor mm Min | Diamater of conductor mm Max | Breaking force Min | Thickness of dielectric mm Average | Thickness of dielectric mm Min | core Outside diameter mm Min | core Outside diameter mm Max |

| Phase or auxiliary or nonstrain- bearing neutral(aluminium) | 16 25 35 50 70 95 120 150 | 6 6 6 6 12 15 15 15 | 1.91 1.20 0.868 0.641 0.443 0.320 0.253 0.206 | 4.6 5.8 6.8 7.9 9.7 11.0 12.5 13.9 | 5.1 6.3 7.3 8.4 10.2 12.0 13.5 15.0 | 2070 3300 4500 6200 8900 12300 15600 19200 | 1.2 1.4 1.6 1.6 1.8 1.8 1.8 1.8 | 0.98 1.16 1.34 1.34 1.52 1.52 1.52 1.52 1.52 | 7.0 8.6 10.0 11.1 13.3 14.6 16.3 17.1 | 7.8 9.4 10.9 12.0 14.2 16.0 17.5 18.6 |

| Service connection (aluminium) | 16 25 | 6 6 | 1.91 1.20 1.83 1.15 0.727 | 4.6 5.6 | 5.6 6.5 | 2070 3300 | 1.2 1.4 | 0.98 1.16 | 7.0 8.6 | 8.0 9.6 |

| Service connection (copper) | 10 15 25 | 6 6 6 | 1.83 1.15 0.727 | _ _ _ | 4.2 5.3 6.6 | 3600 5700 8750 | 1.2 1.2 1.4 | 0.98 0.98 1.16 | 6.2 7.2 8.6 | 7.0 8.0 9.6 |

| Supporting (aluminium) | 54.6 70 | 7*3.15 7*3.50 | 0.63 0.50 | 9.2 10.0 | 9.6 10.4 | 16600 20100 | 1.6 1.6 | 1.34 1.34 | 12.3 12.9 | 13.0 13.6 |