Control cables belong to cables for electrical equipment, which directly transmit electric energy from the power distribution point of the power system to the power connection lines of various electrical equipment and appliances.When producing power cables and control cables of the same specification, the insulation and sheath thickness of the power cables should be thicker.

Rated voltage :Power cables is generally 0.6/1kV and above, Control cables is mainly 450/750V.

The standard for control cables is GB/T 9330, and the standard for power cables is GB12706.

The cross-section of the control cable generally does not exceed 10 square, and the power cable is mainly used to transmit power, and generally has a large cross-section.

Features

- Meet the needs of many electrical appliances

During the production process of industrial control cables, the relevant standards in the process of dissemination of various information are fully considered. This can ensure that industrial control cables can meet the performance of many electrical appliances in daily work. - Strong wear resistance

Industrial control cables basically go underground when they are routed, so the wear resistance is relatively stronger. - Anti-corrosion ability

It has good anti-corrosion ability, which prolongs the service life of industrial control cables and ensures the overall quality of industrial control cables. - Anti-interference effect

In the process of making industrial control cables, special processing technology is used, so that the anti-interference ability of itself can be relatively stronger, especially for important information, which can play a very important in protection .

Application

PVC insulated and PVC sheathed control cables are suitable for industrial and mining enterprises, energy and transportation departments, for control and protection of lines with AC rated voltage below 450/750 volts, etc.

- KVV

KVV Cable 450/750 4-37 0.75-10 Copper-resistant PVC insulated PVC sheath.

Laying indoors, cable trenches, pipelines and other fixed occasions. - KVV22

Copper core PVC insulated PVC sheathed Steel tape armored KVV22 cable 450/750 4-37 0.75-10.

Laying inside, in cable trenches, directly buried pipelines, and other fixed situations that can endure significant mechanical external forces. - KVVP

Flame-retardant copper core, PVC-insulated, and PVC-sheathed KVVP cable 450/750 4-37 0.75-10

laid indoors, in cable trenches, pipes, and other stationary locations requiring shielding - KVVR

Flexible control cable with a copper core, PVC insulation, and a PVC sheath, 450/750 4-37 0.75-10

Indoors, on occasions with mobility needs - KVVRP

copper core, PVC-insulated, PVC-sheathed braided shielded flexible control cable 450/750 4-37 0.75-10

laid indoors when movable shielding is necessary. - ZRKVV

Flame-retardant copper core PVC insulated PVC sheathed ZRKVV cable 450/750 4-37 0.75-10

Laid indoors, cable trenches, pipelines and other fixed occasions that require flame retardancy - ZRKVV22

Copper core PVC insulated PVC sheath braided steel tape armored ZRKVV 22 cable 450/750 4-37 0.75-10

Laid indoors, cable trenches, pipelines directly buried and other places that can withstand large mechanical forces and have flame retardant requirements Fixed occasion - ZRKVVP

Copper core PVC insulated PVC sheathed braided shielded ZRKVVP cable 450/750 4-37 0.75-10

Laid indoors, cable trenches, pipelines and other fixed occasions that require shielding and flame retardancy - ZRKVVR

Copper core PVC insulated PVC sheathed braided ZRKVVR cable 450/750 4-37 0.75-10

Laid indoors, where there are mobile and flame retardant requirements - ZRKVVRP

Copper core PVC insulated PVC sheathed braided shielded ZRKVVP cable 450/750 4-37 0.75-10

Laid indoors where there are requirements for mobile shielding and flame retardancy.

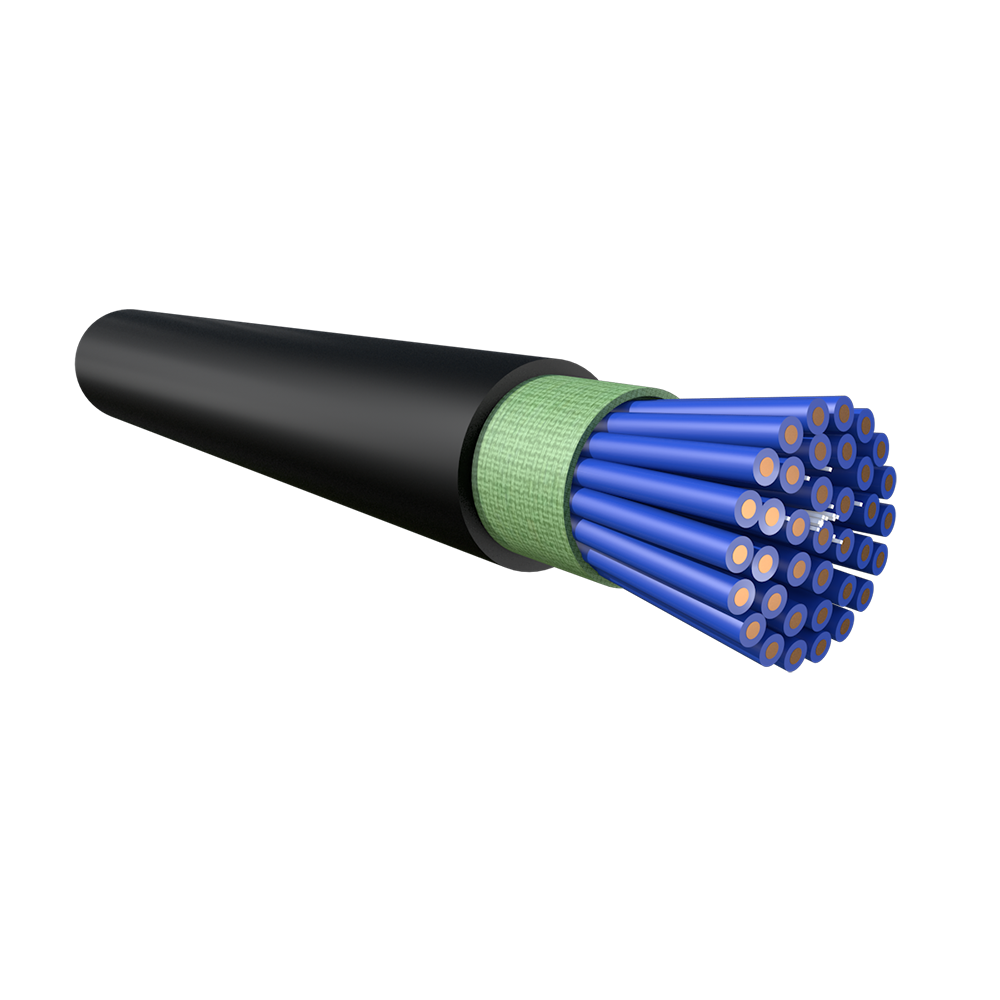

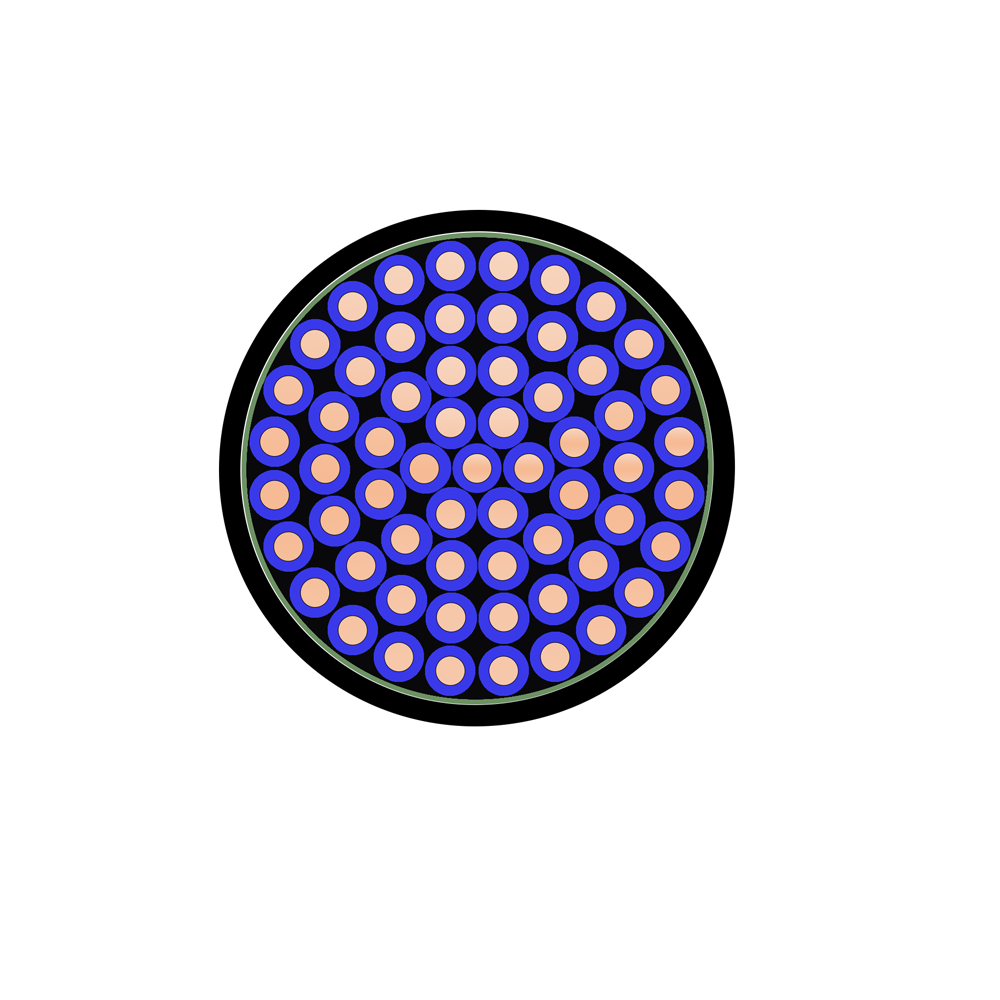

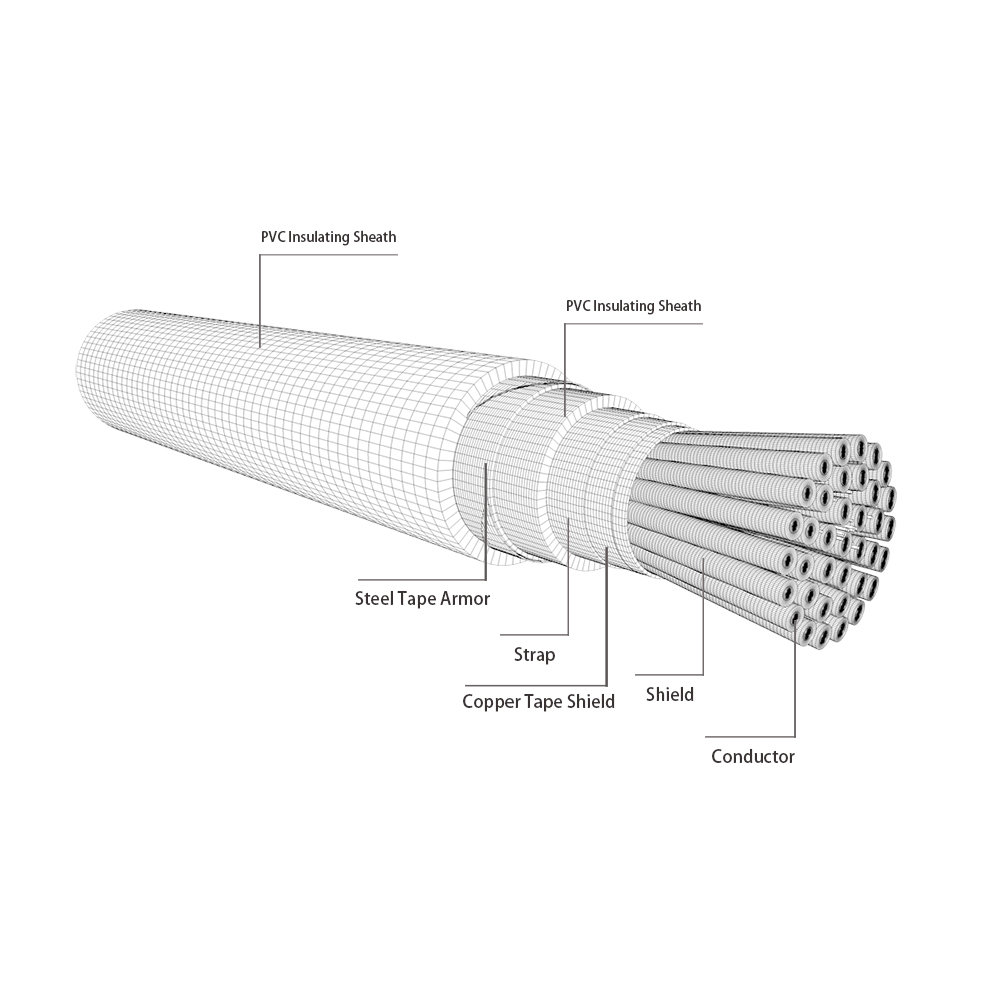

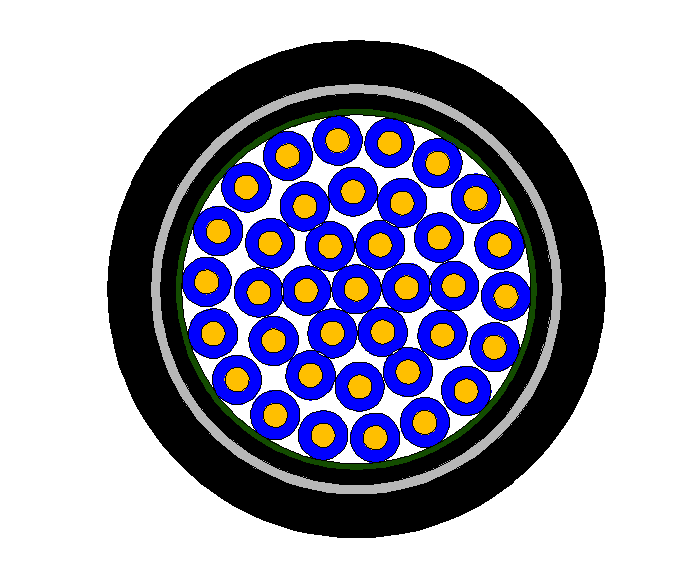

Construction

Performance

| Number of cores × Cross-section | Number of wire in conductor | Nominal thickness of Insulation | Approx. overall diameter | Approx. weight | Max. DC resistance at 20℃ |

| Nos×mm2 | Nos | mm | mm | kg/km | ohm/km |

| 3×1.5A | 1 | 0.8 | 13.3 | 104.0764659 | 12.1 |

| 4×1.5A | 1 | 0.8 | 13.7 | 108.3448724 | 12.1 |

| 5×1.5A | 1 | 0.8 | 14.5 | 115.5194281 | 12.1 |

| 6×1.5A | 1 | 0.8 | 15.4 | 123.420521 | 12.1 |

| 7×1.5A | 1 | 0.8 | 16.3 | 131.6848826 | 12.1 |

| 8×1.5A | 1 | 0.8 | 16.3 | 131.6848826 | 12.1 |

| 10×1.5A | 1 | 0.8 | 17.2 | 139.9492442 | 12.1 |

| 12×1.5A | 1 | 0.8 | 19.3 | 159.2932994 | 12.1 |

| 14×1.5A | 1 | 0.8 | 19.8 | 163.5617059 | 12.1 |

| 16×1.5A | 1 | 0.8 | 20.6 | 170.7362616 | 12.1 |

| 19×1.5A | 1 | 0.8 | 21.5 | 178.6373546 | 12.1 |

| 24×1.5A | 1 | 0.8 | 22.4 | 186.9017162 | 12.1 |

| 27×1.5A | 1 | 0.8 | 25.5 | 222.4096775 | 12.1 |

| 30×1.5A | 1 | 0.8 | 26.1 | 228.9620323 | 12.1 |

| 37×1.5A | 1 | 0.8 | 27.3 | 244.0149007 | 12.1 |

| 2×2.5A | 1 | 0.8 | 29.2 | 270.2262167 | 12.1 |

| 3×2.5A | 1 | 0.8 | 14.0 | 110.97857 | 7.41 |

| 4×2.5A | 1 | 0.8 | 14.6 | 115.7918795 | 7.41 |

| 5×2.5A | 1 | 0.8 | 15.4 | 123.8746068 | 7.41 |

| 6×2.5A | 1 | 0.8 | 16.4 | 132.6838714 | 7.41 |

| 7×2.5A | 1 | 0.8 | 17.4 | 142.0380389 | 7.41 |

| 8×2.5A | 1 | 0.8 | 17.4 | 142.0380389 | 7.41 |

| 10×2.5A | 1 | 0.8 | 18.5 | 151.3922064 | 7.41 |

| 12×2.5A | 1 | 0.8 | 20.9 | 173.0975078 | 7.41 |

| 14×2.5A | 1 | 0.8 | 21.4 | 177.9108173 | 7.41 |

| 16×2.5A | 1 | 0.8 | 22.3 | 185.9935446 | 7.41 |

| 19×2.5A | 1 | 0.8 | 23.3 | 194.8028091 | 7.41 |